Introduction to Plant Scheduling for Asphalt:

Asphalt is a crucial component in the construction industry, used for paving roads, highways, and parking lots. To ensure that your asphalt mix production runs smoothly, it is essential to have an efficient scheduling system in place. In this guide, we will discuss the importance of scheduling in the asphalt industry, the process of scheduling asphalt mix production, and introduce the top asphalt plant scheduling software currently available in the market.

How Asphalt Mix is Scheduled:

Scheduling asphalt mix production involves a series of steps. First, you will need to determine the amount of asphalt required for a project. The quantity, dates, mix designs, load times, contacts and other information can be received from the paving customer, foreman, etc. Then, you can share the asphalt order information with the plant operations team. Next, you will need to calculate the amount of raw materials needed to produce the asphalt, including aggregates, bitumen, and additives. Once you have determined the amount of raw materials required, you can schedule the production of the asphalt mix. Sometimes, you will have input materials that tend to run out. Understanding your raw material needs and sharing them with your suppliers is essential.

Why is Planning Asphalt Pavement Production at Your Plant so Important:

Proper planning and scheduling of asphalt production is essential for several reasons. First, it ensures that you have the necessary amount of asphalt (oil grade, supplier, quantity, etc) on hand to meet customer demand. Similarly with your aggregates, RAP and additives. Second, it helps to reduce waste and minimize the risk of overproduction. Third, it can help to improve the efficiency of your operations, allowing you to produce more asphalt in less time, with fewer startups, and wasted cost. Additionally, it can help to avoid delays in the construction project and improve the overall quality of the pavement. Working with the customer and letting them know when you have potential scheduling issues at the plant is crucial. Having a place where all of your asphalt plant’s order information is stored, shared, and visible to the team can help your operation identify issues more quickly. This way, you can get ahead of the problems and notify your customers early so that they might have time to change their paving plans and work with you.

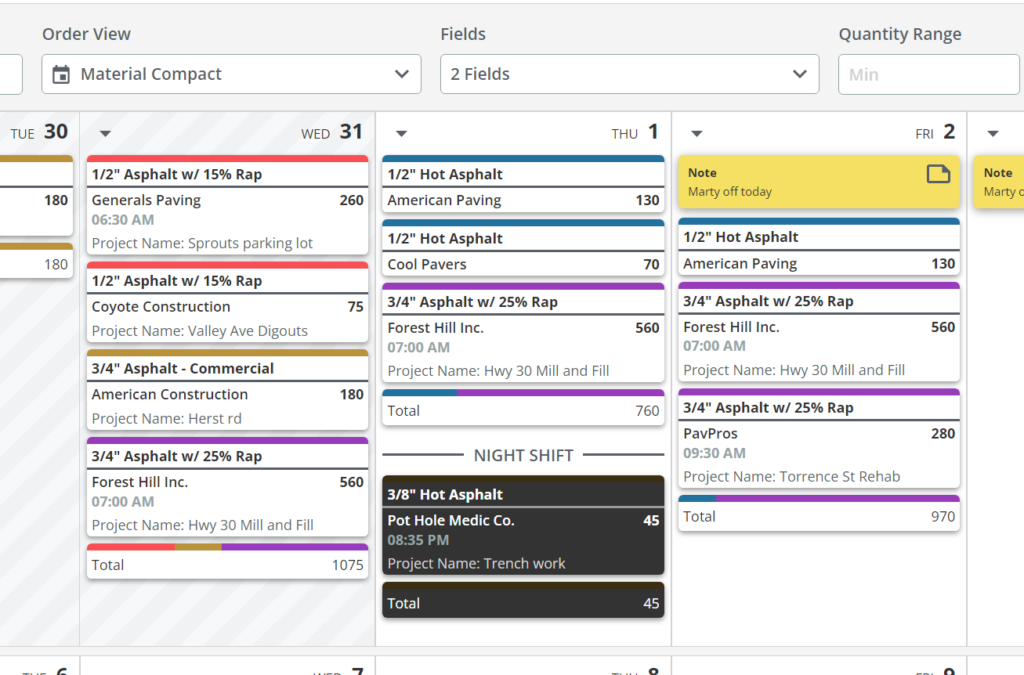

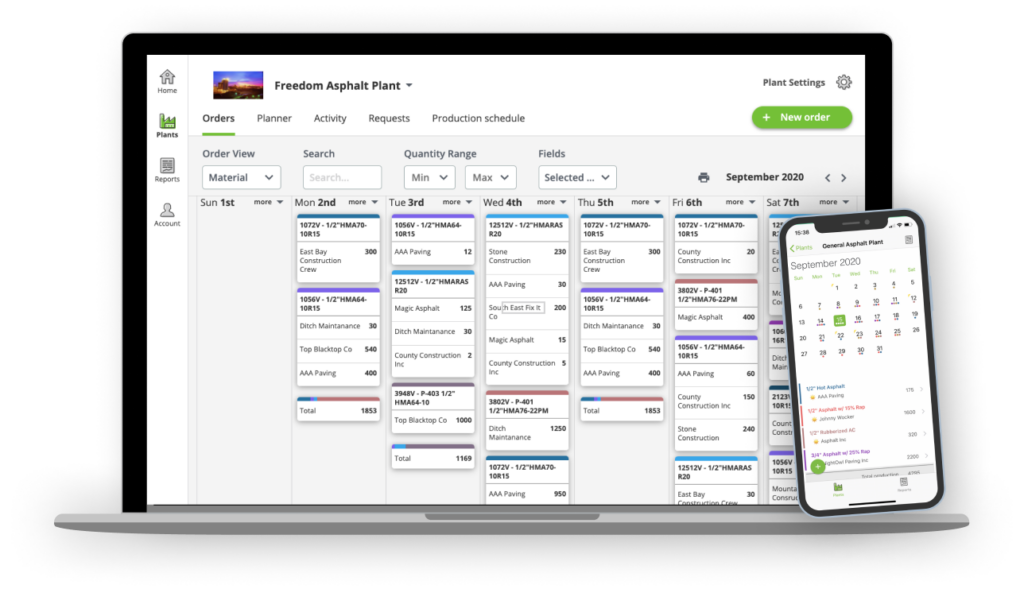

Planning Plant Production with PlantDemand – an Asphalt Plant Scheduling Software:

One solution that can help with asphalt plant scheduling is PlantDemand. This software is designed specifically for the asphalt industry and allows you to easily plan and schedule production, communicate your material needs, identify potential issues with scheduling, and manage customer orders. With PlantDemand, you can access a live real-time order calendar, allowing you to make informed decisions and optimize your operations. Additionally, it allows you to forecast the demand, schedule the production, and optimize the fleet and resources according to the demand.

Conclusion:

Proper planning and scheduling is crucial for success in the asphalt industry. By using an asphalt plant scheduling software solution like PlantDemand, you can improve efficiency, reduce waste, and ensure that you have the necessary amount of asphalt oil, rock, RAP, and additives on hand to meet customer demand. In this guide, we have discussed the importance of scheduling in the asphalt industry, the process of scheduling asphalt mix production, and introduced PlantDemand, a powerful solution that can help you streamline your asphalt production.

- Requesting Asphalt and Aggregate From Your Plant – A Customer Portal Update

- Creating Mix Designs and Materials in PlantDemand

- 8 Common Mistakes in Asphalt Software and Scheduling

- PlantDemand Upgrades Customer Portal for Streamlined Requests and Scheduling

- Ahorra tiempo, mejora la gestión de materiales y la programación de pedidos con PlantDemand

- Customizing Your Asphalt Plant Order Form for Optimal Operations