Recycled Asphalt Pavement (RAP)

Asphalt pavement has been a popular choice for roads and parking lots for many years due to its durability, flexibility, and ability to withstand heavy traffic. However, as the world moves towards a more sustainable future, the need for asphalt pavement recycling is becoming increasingly important.

At its core, asphalt pavement recycling involves using existing pavement materials to create new pavement, rather than disposing of them and starting from scratch. This process not only reduces waste and conserves resources, but it also saves time and money, making it an attractive option for both government agencies and private contractors.

In this article, we will discuss why asphalt pavement recycling is the future of road construction and maintenance, the benefits it offers, and the various methods of recycling asphalt pavement (RAP).

Benefits of Asphalt Pavement Recycling

- Environmental Sustainability

Asphalt pavement recycling is an environmentally sustainable practice as it reduces the need for new raw materials and cuts down on the amount of waste generated. By recycling existing pavement materials, we can conserve natural resources, reduce greenhouse gas emissions, and reduce the amount of waste sent to landfills.

- Cost Savings

One of the most significant benefits of asphalt pavement recycling is cost savings. Recycling materials reduces the need for new raw materials, which can significantly reduce costs. Additionally, recycling asphalt pavement can reduce the need for costly maintenance and repairs, as the recycled material is often more durable than new materials.

- Energy Efficiency

Recycling asphalt pavement requires less energy than producing new materials. The process of creating new asphalt pavement involves heating raw materials to extremely high temperatures, while recycling asphalt pavement only requires reheating the existing materials.

- Improved Durability

Recycled asphalt pavement is often more durable than new materials due to the fact that it contains aged binder, which has been exposed to weathering and oxidation. This aged binder is stronger and more resistant to cracking than new materials, making it ideal for heavy traffic areas.

Methods of Asphalt Pavement Recycling

- Hot In-Place Recycling

Hot in-place recycling involves heating the existing pavement materials, milling the surface to remove any damaged areas, and adding new asphalt binder to create a new surface. This method is most commonly used for small to medium-sized projects.

- Cold In-Place Recycling

Cold in-place recycling is similar to hot in-place recycling, but it involves using a recycling machine to break up the existing pavement, add new materials, and create a new surface. This method is ideal for larger projects as it is faster and more efficient.

- Full-Depth Reclamation

Full-depth reclamation involves using a recycling machine to pulverize the existing pavement, add new materials, and create a new surface. This method is ideal for larger projects where the existing pavement is heavily damaged or in need of replacement.

4. Adding RAP Into the Mix At An Asphalt Plant

Some asphalt mix plants are equipped with methods to introduce a percentage of RAP into new mix. This is done by feeding in the measured proportion and blending it with the hot virgin aggregates and oil.

Asphalt Recycled

Asphalt pavement recycling is the future of road construction and maintenance due to its environmental sustainability, cost savings, energy efficiency, and improved durability. It is important for producers to be able to understand their customer’s needs. This can allow them to schedule their asphalt plant in a way that maximizes the use of RAP in the mixes. The various methods of asphalt pavement recycling, including hot in-place recycling, cold in-place recycling, and full-depth reclamation, offer contractors and government agencies a range of options for recycling existing pavement materials and creating new, durable surfaces.

As we move towards a more sustainable future, it is important to prioritize practices that conserve resources and reduce waste. Asphalt pavement recycling is a crucial step in this direction and is sure to play an essential role in the future of road construction and maintenance.

Sources:

National Asphalt Pavement Association – https://www.asphaltpavement.org/

This website provides valuable information on asphalt pavement recycling, including best practices, case studies, and research.

Federal Highway Administration – https://www.fhwa.dot.gov/pavement/recycling/

The FHWA website offers technical information on various asphalt pavement recycling methods, along with their benefits and limitations.

Asphalt Recycling and Reclaiming Association – https://www.arra.org/

The ARRA is a leading industry association focused on promoting the use of asphalt pavement recycling and reclaiming.

The Asphalt Institute – https://asphaltinstitute.org/

The Asphalt Institute is a nonprofit organization that provides technical expertise and educational resources on asphalt pavement recycling.

Pavement Interactive – https://www.pavementinteractive.org/article/asphalt-pavement-recycling/

This website is an excellent resource for learning about the different methods of asphalt pavement recycling, including their benefits and drawbacks.

Asphalt Contractor Magazine – https://www.forconstructionpros.com/asphalt

Asphalt Contractor Magazine provides industry news, project case studies, and expert insights on asphalt pavement recycling and other topics related to the asphalt industry.

Recycling Today – https://www.recyclingtoday.com/article/using-recycled-pavement-materials-in-new-asphalt-mixtures/

This article from Recycling Today provides an overview of using recycled pavement materials in new asphalt mixtures, including their benefits and potential challenges.

Other posts

-

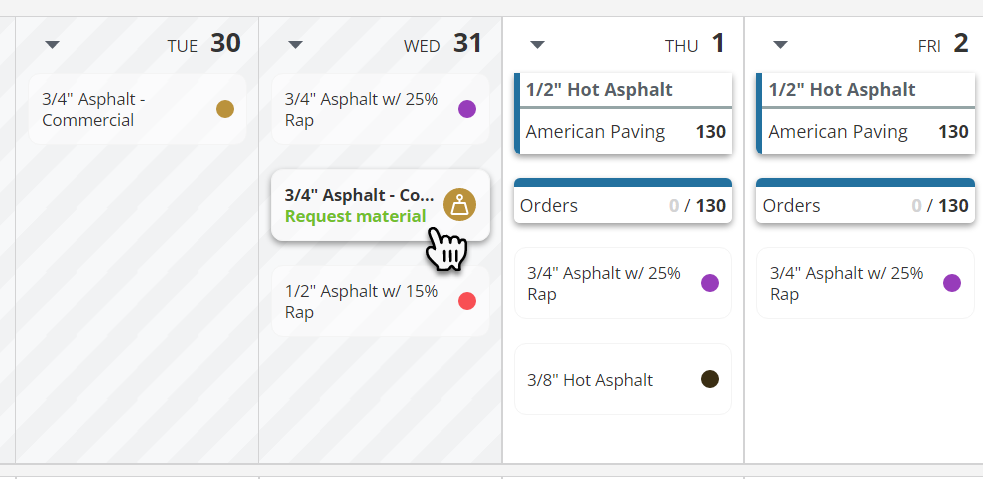

Requesting Asphalt and Aggregate From Your Plant – A Customer Portal Update

Customers can request asphalt and aggregates from your plant The Customer Portal was initially released in PlantDemand to allow customers to submit requests for mix to your plant. They could see the status of their request, and then see it on the calendar once a plant person approved it. While […]

-

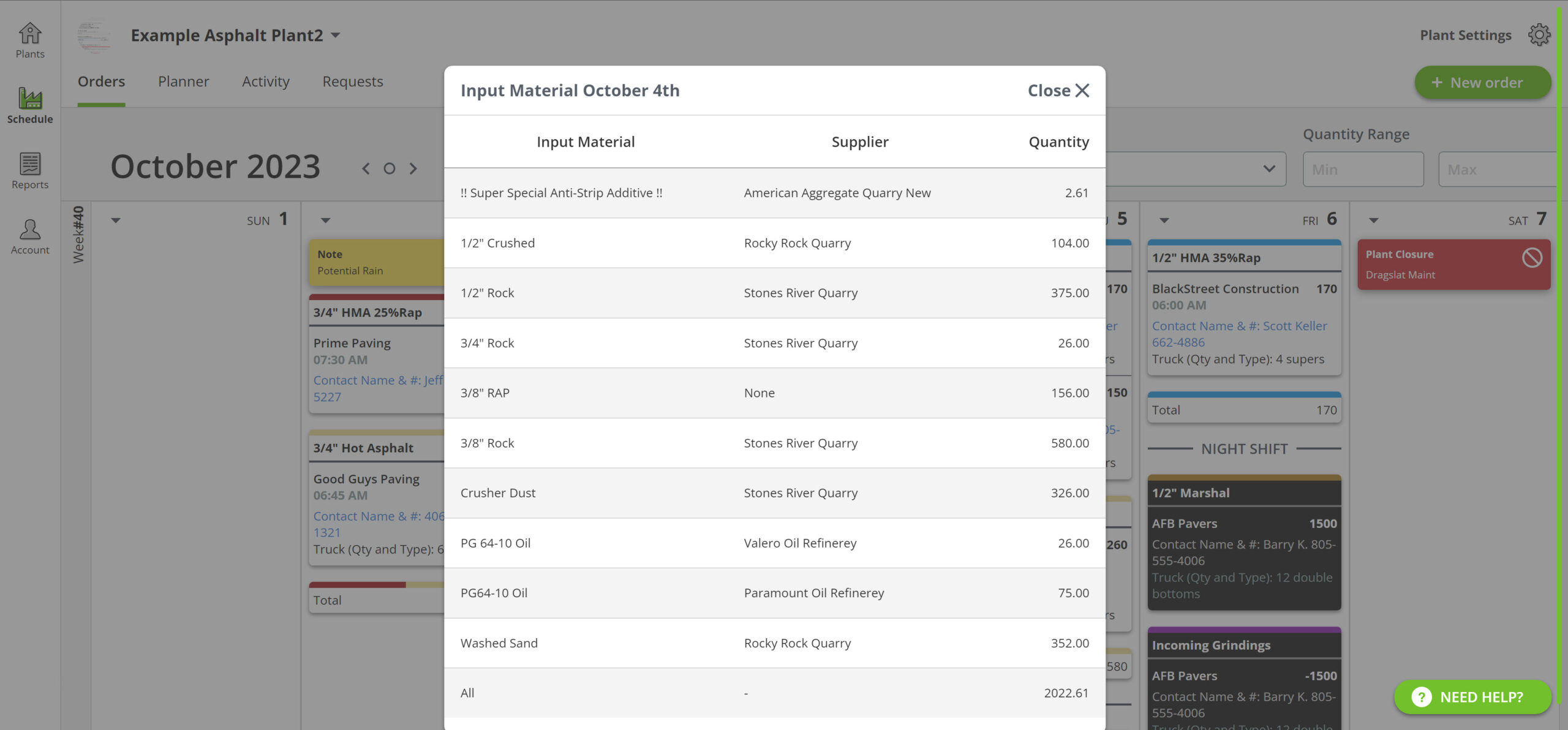

Creating Mix Designs and Materials in PlantDemand

Create Mix Designs and Materials To create materials in PlantDemand, follow the steps below. Edit your mix designs periodically. Make output materials obsolete if your mix design has expired. This will make it so that it can no longer be scheduled, and will put an “Obsolete” tag to the front […]

-

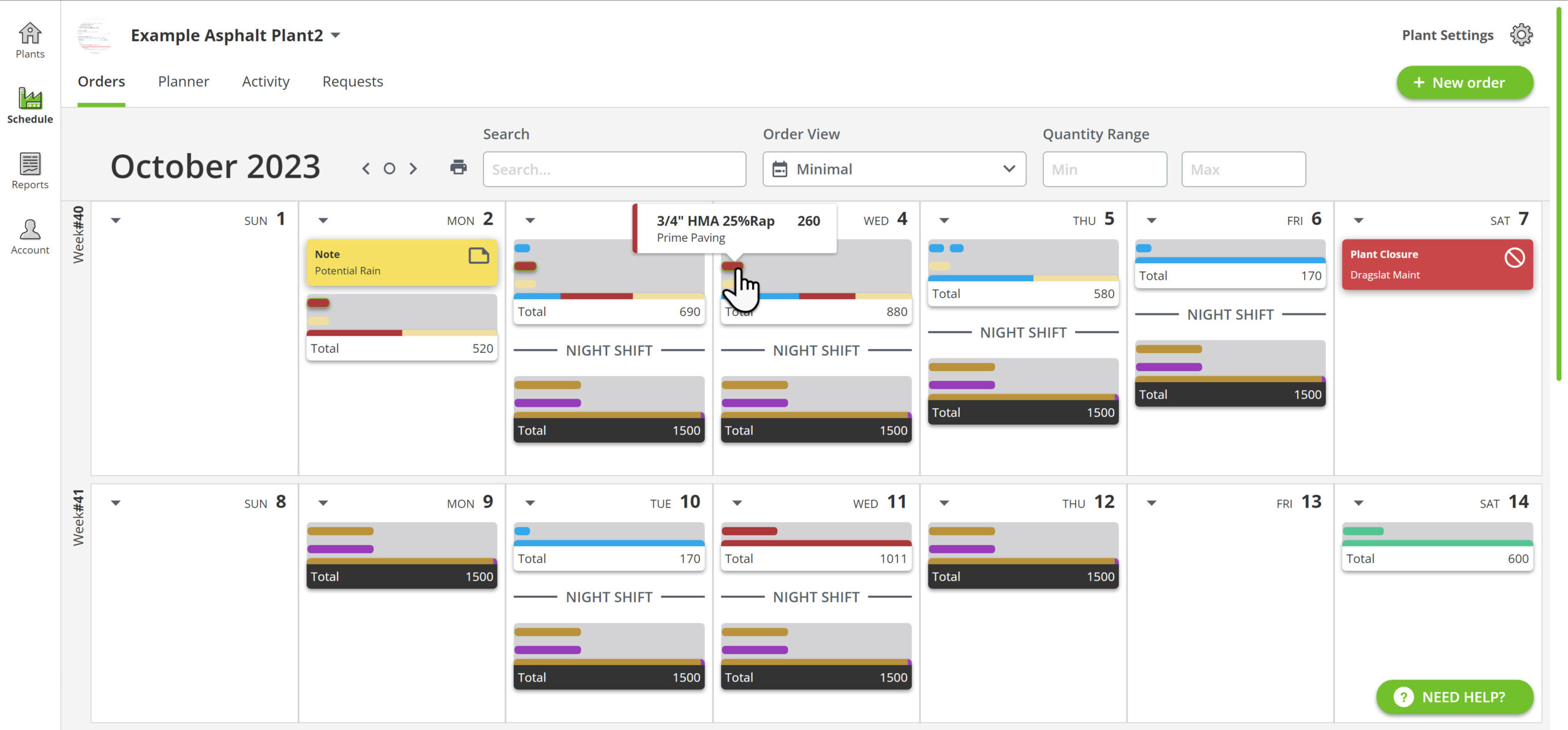

8 Common Mistakes in Asphalt Software and Scheduling

Key Takeaways Aspect Description Calendar Views While the Material View is the default when getting started, many users don’t explore PlantDemand’s other calendar views Important Custom Order Fields Your order form can have fields that are important to your plant and business. Select important fields to show on your calendar […]