Introduction to Asphalt

Asphalt is one of the most commonly used materials for road construction. It is a sticky, black, and highly viscous liquid that is obtained by refining petroleum. Asphalt plants, also known as “hot mix plants” or “black top plants” are facilities that manufacture asphalt and related materials. In this comprehensive guide, we will provide all the necessary information about asphalt plants, including their types, pollution, cost, and more!

What does an asphalt plant do?

Asphalt plants are responsible for producing asphalt and related materials such as tar and bitumen. They take in raw materials such as aggregates, sand, and asphalt cement and heat them to create asphalt. The process involves heating the materials to high temperatures, and then mixing them together to create a homogenous mixture. The mixture is then transported to trucks or storage facilities for future use.

What is a typical hot mix plant?

A typical asphalt plant consists of several components, including a dryer drum, cold feed bins, a conveyor belt, a hot elevator, a vibrating screen, and a storage silo. The dryer drum is where the raw materials are heated to high temperatures to remove any moisture. The hot elevator then transports the heated materials to the vibrating screen, where they are screened to remove any oversized materials. The final mixture is then transported to the storage silo for future use.

What are the two types of asphalt plants?

There are two main types of asphalt plants: batch plants and drum plants. Batch plants produce asphalt in batches, meaning that each batch is made separately and then mixed together. Drum plants, on the other hand, produce asphalt continuously. In drum plants, the raw materials are continuously fed into the drum, and the final product is continuously discharged from the other end.

What are 3 types of asphalt?

There are three main types of asphalt: hot mix asphalt, warm mix asphalt, and cold mix asphalt. Hot mix asphalt is the most commonly used type of asphalt and is produced at high temperatures. Warm mix asphalt is produced at lower temperatures, making it more environmentally friendly. Cold mix asphalt is produced at ambient temperatures and is used for temporary repairs.

How hot is asphalt from the plant?

The temperature of asphalt from the plant can vary depending on the type of asphalt being produced and the specific plant. However, the temperature of hot mix asphalt is typically between 300 and 350 degrees Fahrenheit.

How toxic are blacktop plants?

Asphalt plants can produce emissions that are harmful to human health and the environment. The emissions can include volatile organic compounds, particulate matter, and carbon monoxide. These emissions can cause respiratory problems, headaches, and other health issues. However, modern asphalt plants have advanced pollution control equipment that helps reduce these emissions.

Do asphalt plants cause pollution?

Yes, asphalt plants can cause pollution if they are not properly managed. However, modern asphalt plants have advanced pollution control equipment that helps reduce emissions and minimize their impact on the environment.

Is laying asphalt a good job?

Laying asphalt can be a good job for those who enjoy working with their hands and being outdoors. It can also be a physically demanding job that requires heavy lifting and standing for long periods of time.

Is working with asphalt hard?

Working with asphalt can be hard due to the physical demands of the job. It requires heavy lifting, bending, and standing for long periods of time. It also involves working in hot and noisy environments.

Why do asphalt plants shut down in the winter?

Asphalt plants are typically shut down in the winter because the production of hot-mix asphalt requires high temperatures that cannot be maintained in cold weather. The cold temperatures also make it difficult to transport the asphalt to construction sites, where it needs to be laid down while it is still hot and pliable.

What fuel is used for running a plant?

The most common fuels used in asphalt plants are natural gas, propane, and diesel. Natural gas is the most popular choice because it is readily available and burns cleanly, producing lower emissions than other fuels. Propane is also a good option, but it can be more expensive than natural gas. Diesel is used in some older plants, but it is not as environmentally friendly as natural gas or propane.

What are the two main types of hot mix plants?

There are two main types of asphalt plants: batch plants and drum plants. Batch plants produce asphalt in batches, while drum plants produce asphalt continuously. Batch plants are usually more expensive to operate because they require more labor, but they are better suited for small projects. Drum plants are more efficient and are better suited for large-scale projects.

What are 3 types of asphalt?

The three main types of asphalt are hot-mix asphalt, warm-mix asphalt, and cold-mix asphalt. Hot-mix asphalt is the most common type and is produced at high temperatures. Warm-mix asphalt is produced at lower temperatures and is becoming more popular because it is more environmentally friendly. Cold-mix asphalt is produced at even lower temperatures and is used mainly for temporary repairs.

Is asphalt stronger than concrete?

Asphalt and concrete are both strong materials, but they have different strengths and weaknesses. Asphalt is more flexible than concrete and can withstand more movement without cracking. Concrete, on the other hand, is more rigid and can withstand heavier loads without deforming. Ultimately, the choice between asphalt and concrete depends on the specific needs of the project.

How much does an blacktop plant cost?

The cost of an asphalt plant can vary greatly depending on its size and type. Small plants cost around $100,000, while large plants can cost millions of dollars. Additionally, the cost of operating an asphalt plant can be high due to the cost of fuel and maintenance.

How hot is asphalt from the plant?

The temperature of asphalt from an asphalt plant can range from 280 to 350 degrees Fahrenheit, depending on the type of asphalt being produced. The temperature of the asphalt is critical because it needs to be hot enough to be pliable but not so hot that it becomes too viscous to work with.

Who is the biggest producer of asphalt?

The United States is the largest producer of asphalt in the world, with China coming in second. Other major producers include Canada, Japan, and Russia.

What is the lifespan of asphalt?

The lifespan of asphalt depends on various factors such as weather, traffic, maintenance, and quality of the mix used. On average, asphalt can last up to 20 years if properly maintained. However, if exposed to extreme weather conditions and heavy traffic, the lifespan can be shorter.

Is asphalt toxic in soil?

Asphalt is not toxic in soil as it is a stable material and does not break down easily. However, if asphalt is mixed with other contaminants such as heavy metals, it can pose a threat to the environment. Therefore, proper disposal of asphalt and monitoring of its use in construction is crucial.

Why is asphalt used instead of concrete?

Asphalt is preferred over concrete for road construction due to its flexibility and ability to withstand temperature changes. Asphalt can expand and contract with temperature changes without cracking, which makes it ideal for regions with extreme weather conditions. Additionally, asphalt has a shorter curing time and can be installed faster than concrete.

How do you maintain an asphalt plant?

Proper maintenance of an asphalt plant is essential to ensure its longevity and efficient operation. Some essential maintenance tips include:

- Regularly inspecting the equipment and making necessary repairs or replacements.

- Keeping the plant clean and free of debris.

- Properly storing and handling materials.

- Ensuring that the plant is properly calibrated for accurate mixing and production.

- Regularly monitoring and maintaining air quality and emissions.

What is part of an asphalt plant?

An asphalt plant consists of several parts that work together to produce asphalt mix. The major components include the cold feed bins, conveyor belt, drum dryer, burner, dust collector, hot elevator, and storage silos. Each component plays a crucial role in the manufacturing process, and any malfunction can affect the quality of the mix produced.

How do you install an asphalt plant?

Installation of an asphalt plant requires careful planning and coordination. The process involves site preparation, equipment delivery, assembly, and testing. Proper installation is essential for the smooth operation of the plant and the quality of the mix produced.

How is asphalt made in a plant?

Asphalt is made in an asphalt plant by combining aggregates, bitumen, and other additives. The aggregates are heated to a certain temperature and then mixed with bitumen in the drum dryer. The mix is then transported to the storage silos and ready for use in road construction.

In conclusion, asphalt plants play a critical role in road construction, and proper understanding of their lifespan, toxicity in soil, maintenance, installation, and manufacturing process is essential. By following the guidelines provided in this article, you can ensure the efficient and smooth operation of an asphalt plant and the production of high-quality asphalt mix.

How can you use PlantDemand for scheduling an asphalt plant?

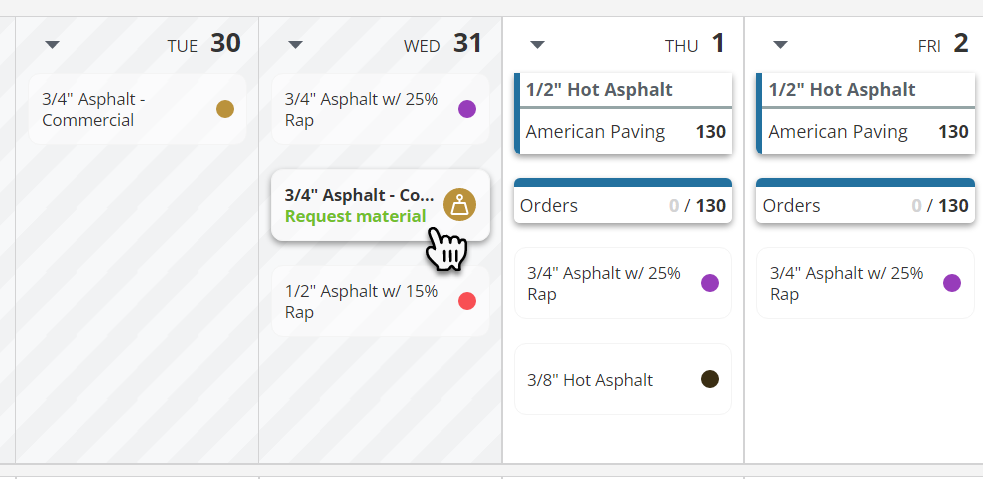

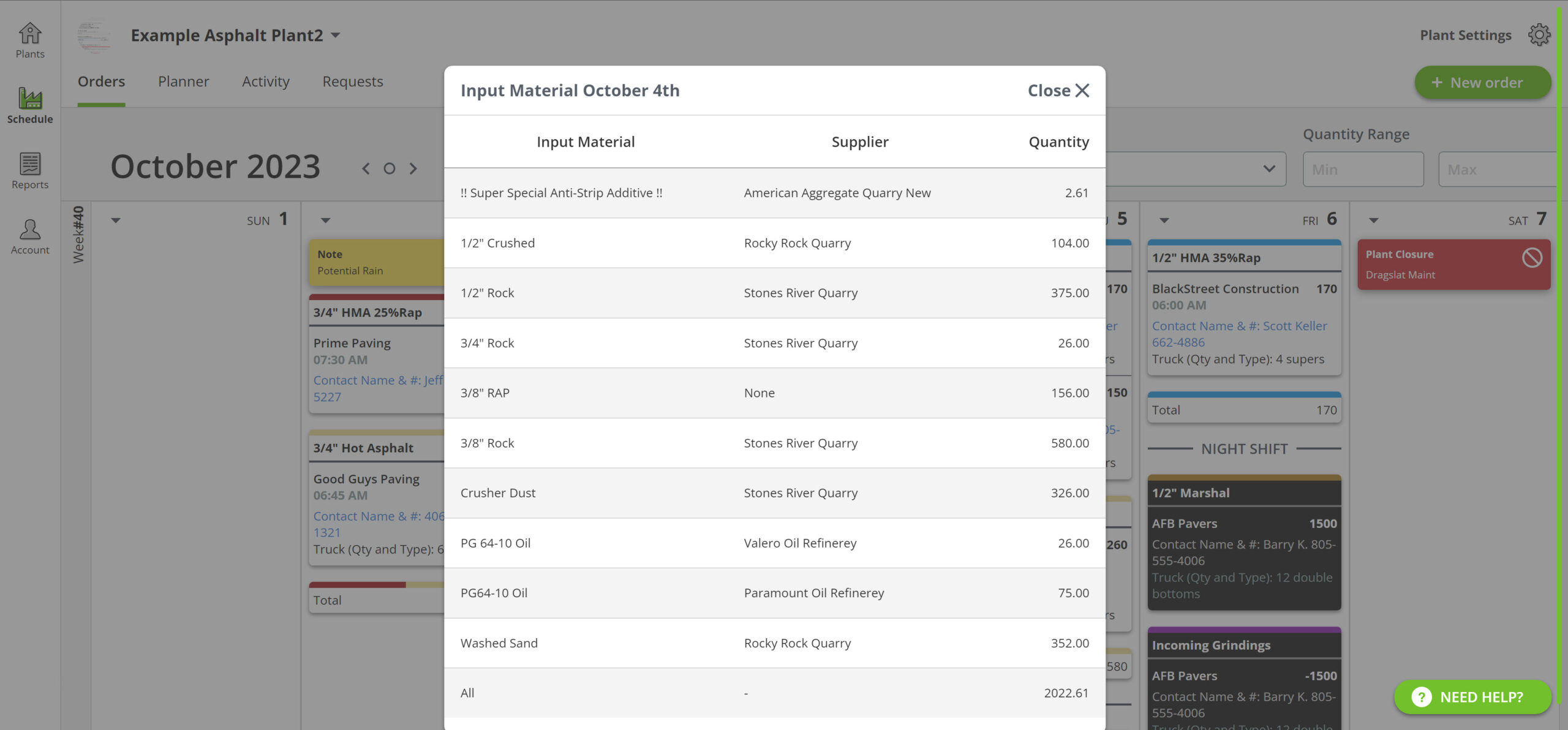

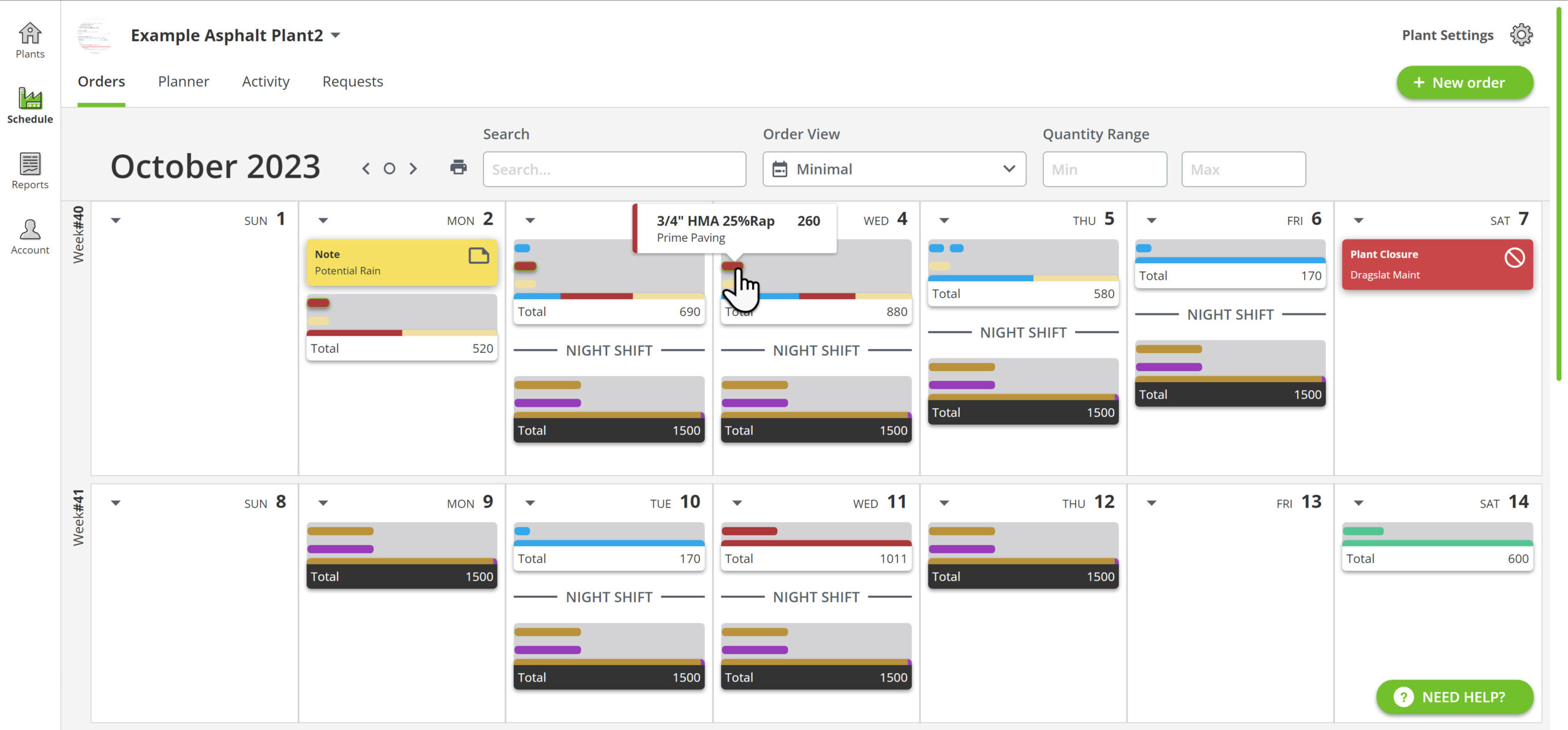

PlantDemand is an asphalt software program that helps asphalt plant operators streamline their scheduling and production processes. With PlantDemand, operators can:

- Create production schedules based on demand and available resources.

- Monitor and adjust for issues in real-time to ensure efficient use of resources.

- Manage inventory and to direct delivery schedules.

- Allow customers to request mix through the Customer Portal.

Conclusion

Asphalt plants are crucial for building and maintaining roads and highways. Understanding the lifespan of asphalt, potential toxicity, reasons for its use over concrete, and proper maintenance can help ensure their efficient and safe operation. Additionally, software programs like PlantDemand can help streamline the scheduling and production process for asphalt plants, leading to increased efficiency and cost savings.

Sources:

- “Asphalt Pavement Alliance.” Lifespan of Asphalt Pavement, www.asphaltroads.org/lifespan-of-asphalt-pavement/.

- “National Asphalt Pavement Association.” Environmental, Health, and Safety Guidelines for Asphalt Pavement Manufacturing, www.asphaltpavement.org/wp-content/uploads/2016/11/EHS_Asphalt_Pavement_Manufacturing-5-5-16.pdf.

- “Asphalt Pavement Alliance.” Why Asphalt?, asphaltroads.org/why-asphalt/.

- “PlantDemand.” PlantDemand, https://plantdemand.com/site/asphalt-plant-scheduling/.

- https://www.asphaltmagazine.com/lifecycle-of-a-porous-asphalt-pavement/

- https://www.epa.gov/sites/production/files/documents/epa_asphalt_industry_overview_1996_0.pdf

- https://www.roadsbridges.com/paving-maintenance-tips-produce-longer-lasting-more-durable-pavement

Other Posts on PlantDemand

-

Requesting Asphalt and Aggregate From Your Plant – A Customer Portal Update

Customers can request asphalt and aggregates from your plant The Customer Portal was initially released in PlantDemand to allow customers to submit requests for mix to your plant. They could see the status of their request, and then see it on the calendar once a plant person approved it. While […]

-

Creating Mix Designs and Materials in PlantDemand

Create Mix Designs and Materials To create materials in PlantDemand, follow the steps below. Edit your mix designs periodically. Make output materials obsolete if your mix design has expired. This will make it so that it can no longer be scheduled, and will put an “Obsolete” tag to the front […]

-

8 Common Mistakes in Asphalt Software and Scheduling

Key Takeaways Aspect Description Calendar Views While the Material View is the default when getting started, many users don’t explore PlantDemand’s other calendar views Important Custom Order Fields Your order form can have fields that are important to your plant and business. Select important fields to show on your calendar […]