Plant scheduling is an essential process in the manufacturing industry that helps optimize production, reduce costs, and improve overall efficiency. However, many manufacturers struggle to understand this critical process, leading to poor production planning and execution. In this article, we will provide a comprehensive guide to help you understand plant scheduling better. We will cover the basics of plant scheduling, the different types of schedules, the benefits of effective plant scheduling, and how to develop and implement a successful scheduling plan.

Table of Contents

- Introduction

- What is Plant Scheduling?

- Types of Plant Scheduling

- Production Scheduling

- Material Scheduling

- Maintenance Scheduling

- Delivery Scheduling

- Benefits of Effective Plant Scheduling

- Improved Production Efficiency

- Reduced Costs

- Increased Customer Satisfaction

- Developing a Plant Scheduling Plan

- Analyze the Current Production Process

- Set Production Goals and Objectives

- Determine Production Capacity

- Create a Master Production Schedule

- Develop Detailed Schedules for Each Production Stage

- Monitor and Adjust the Schedule as Needed

- Implementing a Plant Scheduling Plan

- Train and Educate Employees

- Use Technology to Enhance the Process

- Monitor and Evaluate Performance

- Conclusion

- FAQs

What is Plant Scheduling?

Plant scheduling is the process of planning and organizing production activities to ensure optimal use of resources, reduce downtime, and improve overall efficiency. It involves determining the right quantity and mix of products to produce, scheduling the production process, and managing the resources required to meet production goals.

Effective plant scheduling requires a deep understanding of the production process, the available resources, and the desired output. It involves developing a production plan that considers the constraints and limitations of the production environment while maximizing output.

Types of Plant Scheduling

There are several types of plant scheduling, including production scheduling, material scheduling, maintenance scheduling, and delivery scheduling.

Production Scheduling

Production scheduling is the process of determining the most efficient way to produce goods by optimizing resources such as machines, labor, and raw materials. It involves determining the order in which products are produced and the time required for each production stage.

Material Scheduling

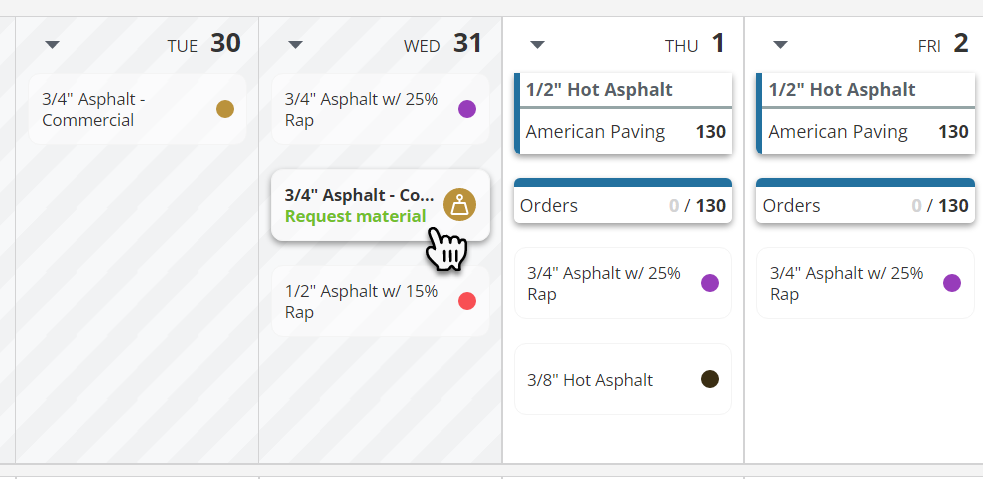

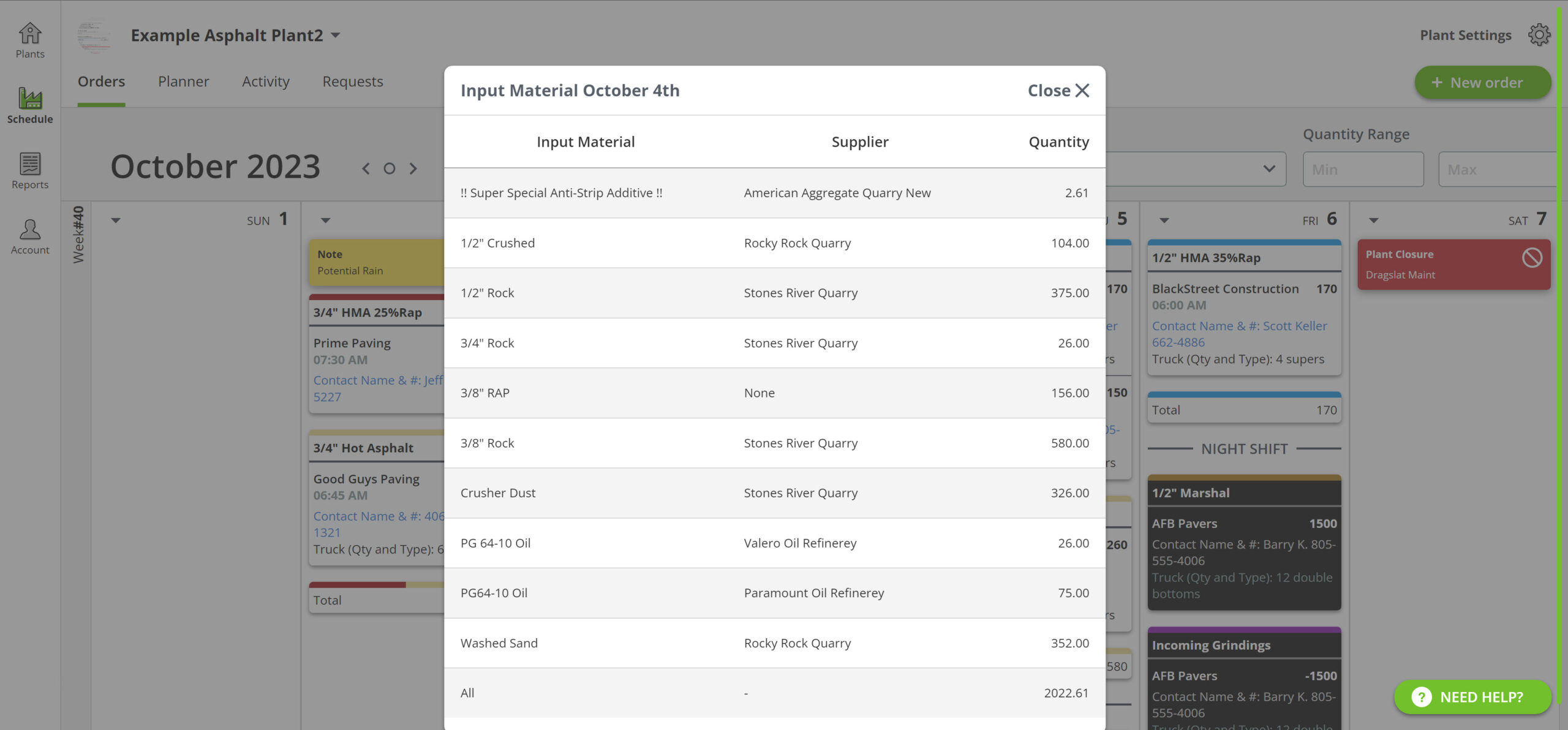

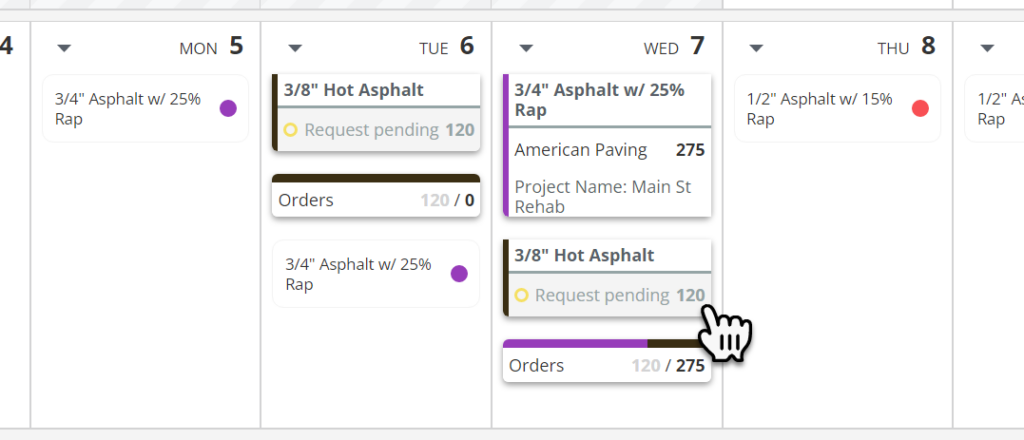

Material scheduling involves determining the materials required for production, the quantity needed, and the time of delivery. This type of asphalt scheduling is essential in ensuring that the necessary materials are available when needed to minimize downtime and delays in the production process.

Maintenance Scheduling

Maintenance scheduling involves planning and scheduling maintenance activities to ensure that production equipment is operating at peak efficiency. This type of scheduling is essential in preventing equipment failure and minimizing downtime.

Delivery Scheduling

Delivery scheduling involves determining the most efficient way to deliver finished goods to customers. It involves determining the delivery route, mode of transportation, and delivery time to ensure that products are delivered on time and at the lowest cost.

Benefits of Effective Plant Scheduling

Effective plant scheduling has several benefits, including improved production efficiency, reduced costs, and increased customer satisfaction.

Improved Production Efficiency

Effective plant scheduling helps minimize downtime, optimize resource utilization, and ensure that the production process runs smoothly. This results in increased production efficiency and output, which translates to improved profits.

Reduced Costs

Effective plant scheduling helps reduce production costs by minimizing waste, optimizing resource utilization, and ensuring that production is aligned with demand. This results in reduced inventory holding costs, reduced labor costs, and improved overall cost efficiency.

Increased Customer Satisfaction

Effective plant scheduling helps ensure that products are produced on time and at the desired quality, resulting in increased customer satisfaction. This translates to improved customer loyalty and increased sales.

Developing a Plant Scheduling Plan

Developing a successful plant scheduling plan involves several steps that should be followed to ensure that the production process is optimized and resources are utilized effectively. The following are the essential steps to follow when developing a plant scheduling plan:

Analyze the Current Production Process

The first step in developing a plant scheduling plan is to analyze the current production process. This involves identifying the production stages, the resources required, and the time required for each stage. By analyzing the current production process, you can identify inefficiencies and areas for improvement, which can be addressed in the scheduling plan.

Set Production Goals and Objectives

After analyzing the production process, the next step is to set production goals and objectives. This involves determining the desired output, the required quality, and the timeframe for production. By setting clear goals and objectives, you can develop a production plan that aligns with your business objectives.

Determine Production Capacity

The next step in developing a plant scheduling plan is to determine production capacity. This involves identifying the maximum output that can be produced with the available resources, such as machines, labor, and raw materials. By determining production capacity, you can develop a realistic production plan that maximizes output while minimizing downtime.

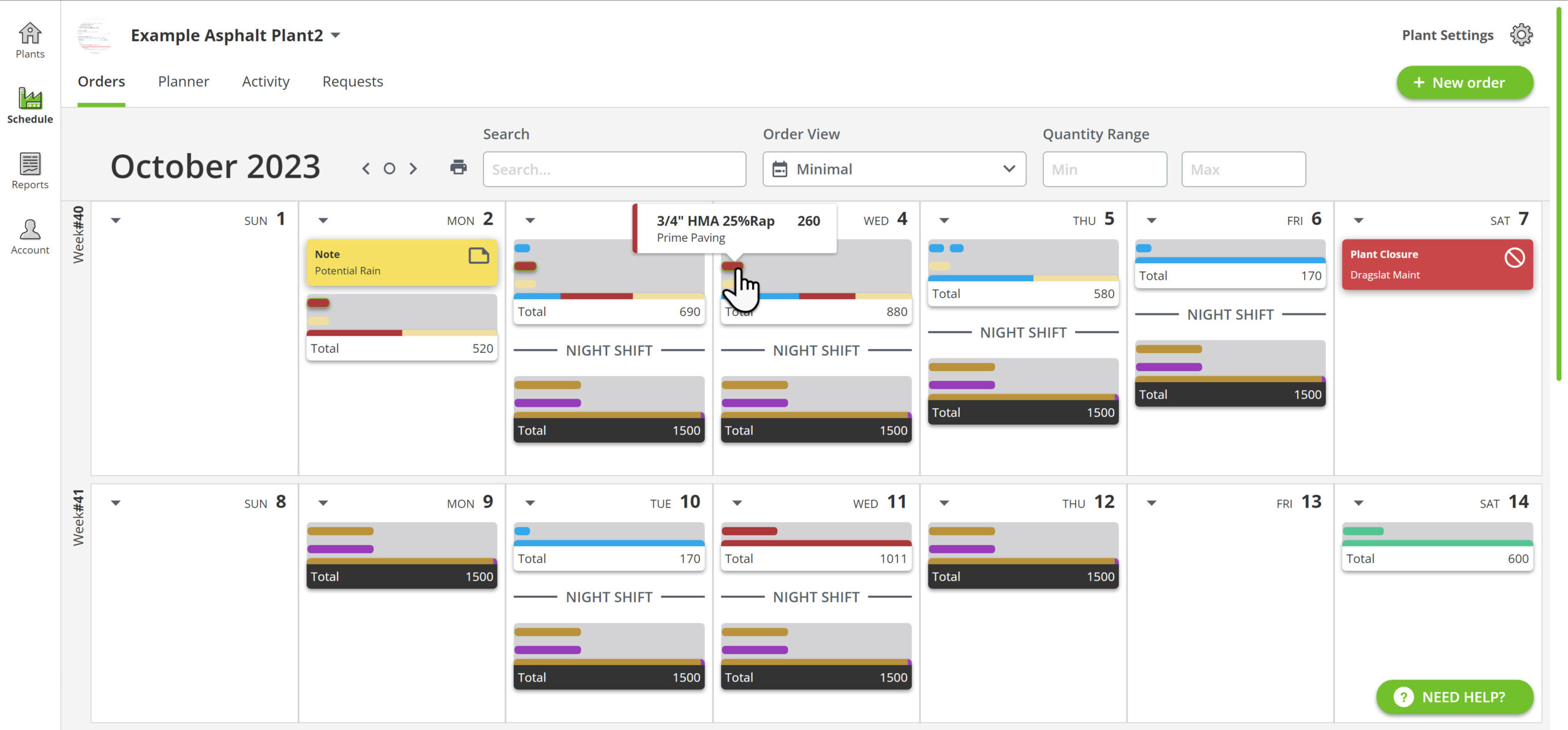

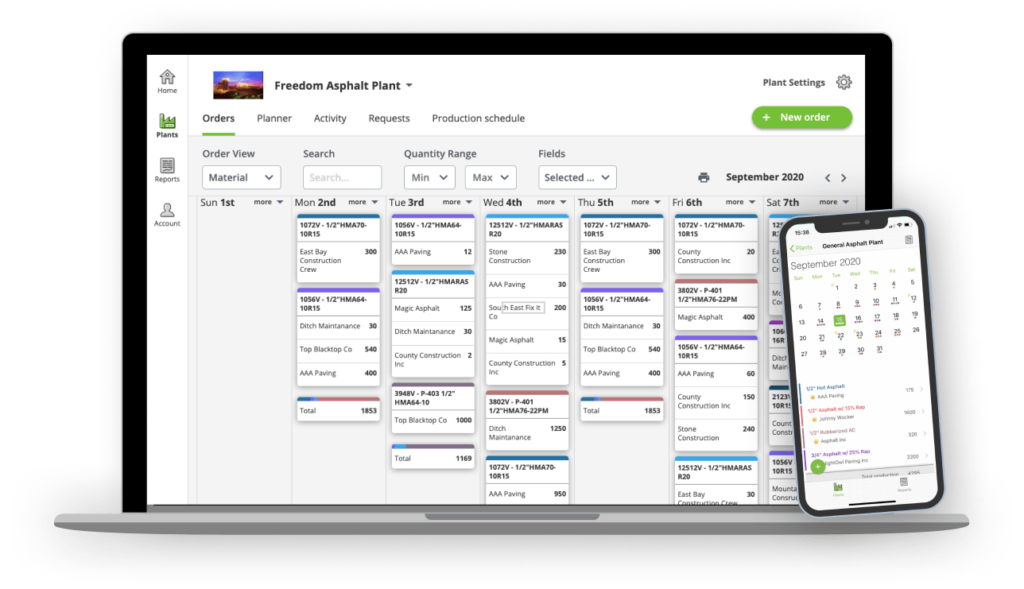

Create a Master Production Schedule

The master production schedule (MPS) is a plan that outlines the production schedule for a specific period, usually a week or a month. The MPS should consider the production goals, production capacity, and customer demand. The MPS serves as a guide for the detailed scheduling of each production stage.

Develop Detailed Schedules for Each Production Stage

After creating the MPS, the next step is to develop detailed schedules for each production stage. This involves determining the time required for each stage and the resources needed. By developing detailed schedules, you can ensure that each production stage is completed on time and that the production process runs smoothly.

Monitor and Adjust the Schedule as Needed

The final step in developing a plant scheduling plan is to monitor and adjust the schedule as needed. This involves tracking production progress, identifying bottlenecks, and making adjustments to the production plan. By monitoring and adjusting the schedule, you can ensure that the production process is optimized, and resources are utilized effectively.

Implementing a Plant Scheduling Plan

Implementing a plant scheduling plan involves several steps that should be followed to ensure that the plan is successful. The following are the essential steps to follow when implementing a plant scheduling plan:

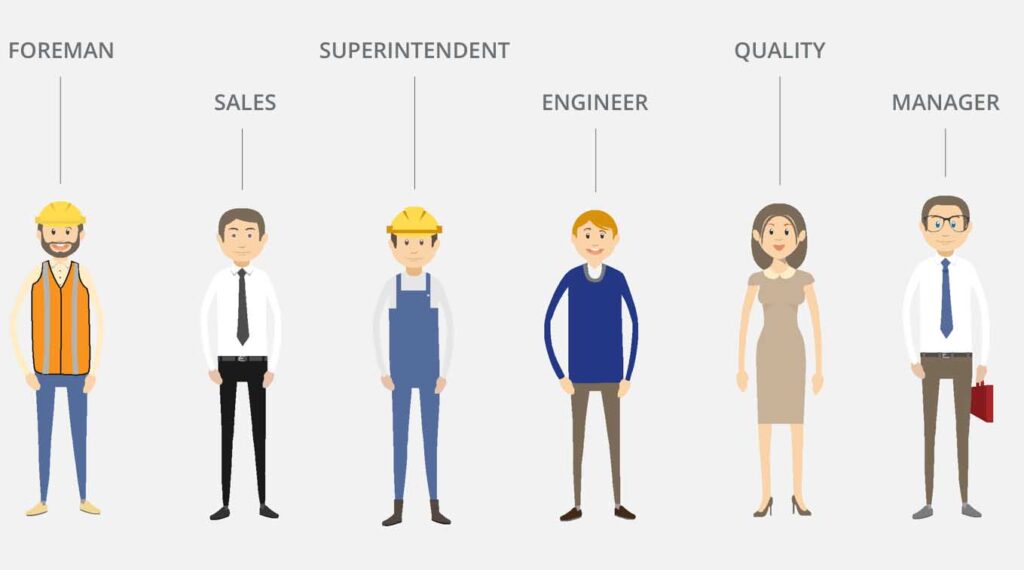

Train and Educate Employees

Employees play a critical role in the success of a plant scheduling plan. It is essential to train and educate employees on the new scheduling plan, including their roles and responsibilities. By ensuring that employees understand the new plan, they can contribute to its success.

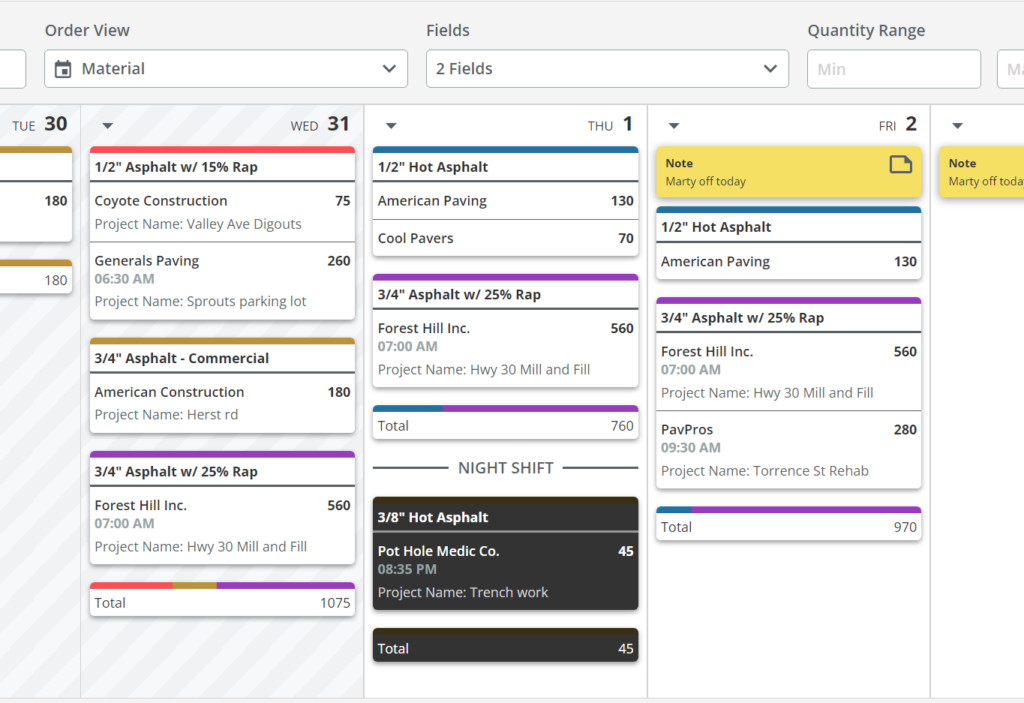

Use Technology to Enhance the Process

Technology can help enhance the plant scheduling process by providing real-time data and insights into the production process. This can help identify bottlenecks, track production progress, and make adjustments to the production plan as needed. By leveraging technology, you can improve the efficiency and effectiveness of the plant scheduling process. This is where PlantDemand can help!

Monitor and Evaluate Performance

The final step in implementing a plant scheduling plan is to monitor and evaluate performance. This involves tracking production progress, identifying areas for improvement, and making adjustments to the production plan. By monitoring and evaluating performance, you can ensure that the plant scheduling plan is successful and that resources are utilized effectively.

Conclusion

Plant scheduling is a critical process in the manufacturing industry that helps optimize production, reduce costs, and improve overall efficiency. By understanding the basics of plant scheduling, the different types of schedules, and the benefits of effective plant scheduling, you can develop and implement a successful scheduling plan. Remember to analyze the current production process, set production goals and objectives, determine production capacity, create a master production schedule, develop detailed schedules for each production stage, and monitor and adjust the schedule as needed. Implementing a plant scheduling plan involves training and educating employees, leveraging technology to enhance the process, and monitoring and evaluating performance.

FAQs

- What is plant scheduling?

Plant scheduling is a process used in manufacturing to optimize production by ensuring that resources are utilized effectively and production goals are met.

- What are the benefits of plant scheduling?

Effective plant scheduling can lead to reduced costs, improved efficiency, and increased productivity.

- What are the different types of schedules used in plant scheduling?

The different types of schedules used in plant scheduling include master production schedules, detailed schedules for each production stage, and real-time schedules.

- How can technology help enhance the plant scheduling process?

Technology can provide real-time data and insights into the production process, allowing for better tracking of production progress and identification of bottlenecks.

- How can plant scheduling be adjusted as needed?

Plant scheduling can be adjusted as needed by monitoring production progress, identifying bottlenecks, and making adjustments to the production plan accordingly.

-

Requesting Asphalt and Aggregate From Your Plant – A Customer Portal Update

Customers can request asphalt and aggregates from your plant The Customer Portal was initially released in PlantDemand to allow customers to submit requests for mix to your plant. They could see the status of their request, and then see it on the calendar once a plant person approved it. While […]

-

Creating Mix Designs and Materials in PlantDemand

Create Mix Designs and Materials To create materials in PlantDemand, follow the steps below. Edit your mix designs periodically. Make output materials obsolete if your mix design has expired. This will make it so that it can no longer be scheduled, and will put an “Obsolete” tag to the front […]

-

8 Common Mistakes in Asphalt Software and Scheduling

Key Takeaways Aspect Description Calendar Views While the Material View is the default when getting started, many users don’t explore PlantDemand’s other calendar views Important Custom Order Fields Your order form can have fields that are important to your plant and business. Select important fields to show on your calendar […]

Sources:

- “Understanding the Importance of Production Scheduling in Manufacturing” by Mark Cubitt, Manufacturing Global. Available at: https://www.manufacturingglobal.com/lean-manufacturing/understanding-importance-production-scheduling-manufacturing

- “Plant Scheduling: A Key to Effective Operations” by Len Calderone, Manufacturing.net. Available at: https://www.manufacturing.net/operations/article/13168153/plant-scheduling-a-key-to-effective-operations

- “Plant Scheduling: The Key to Maximizing Efficiency” by Joel Rubin, Quality Digest. Available at: https://www.qualitydigest.com/inside/lean-article/plant-scheduling-key-maximizing-efficiency.html

- “The Benefits of Effective Scheduling in Manufacturing” by Raj Kesaraju, IndustryWeek. Available at: https://www.industryweek.com/operations/article/22029498/the-benefits-of-effective-scheduling-in-manufacturing