{6 minute read}

It was a typical foggy day in San Francisco. Ernest Ransome was a young engineer and architect, and had just built the very first reinforced concrete bridge in North America. The bridge was 20ft long and 64ft wide, centered in the beautiful Golden Gate Park. It was 1889, and his new, innovative technique for twisting square steel to create a stronger reinforcement was about to be put to the test. Unfortunately, Ernest would leave San Francisco shortly after because–like many at the time–the San Francisco building community was indifferent to innovation with regard to concrete construction and were unaware of the catastrophic 1906 earthquake and fire that were soon to come.

Today we are in an interesting era in the world of Construction Material Manufacturing. Technology from the stone age and the future combine together like the very mix our plants create and sell. The unchanged particles of rock, are broken, sorted, combined and bound together with machinery that has been tested and tuned–iterating through subtle changes, making these machines more reliable, and consistent.

Plant automation has grown from operators pulling levers to batch mix, to practically being able to run the plant remotely from their living room, while throwing back a frosty pint with their fellow operators. Although this is probably not preferable (or allowed), especially to agencies like OSHA or MSHA, it is most likely a possible scenario nowadays with systems like the Astec TCII or COMMANDbatch and many other options for aggregate plants and quarries. The input-output feedback loop is getting smarter, and automation of the plant is slowly progressing. Warren Bennis once said, “The factory of the future will have only two employees, a man and a dog. The man will be there to feed the dog. The dog will be there to keep the man from touching the equipment.”

What do you expect from your plant operator or foreman?

Even if the above quote comes true in our plants, while technology grows, the plant operators find themselves in more of an admin and sales role as they run the plant with newer automation. They are given tasks like safety, environmental, training others, dealing with MSHA inspectors and more.

Sound about right?

The fact is, plants have come a long way in how they produce process rock. The process has been looked at over and over. The machinery has been built and rebuilt. And the mixes have been designed and redesigned. But what about BEFORE the rock must be made and sold?

The Current Struggle of Scheduling your Quarry or Rock Plant

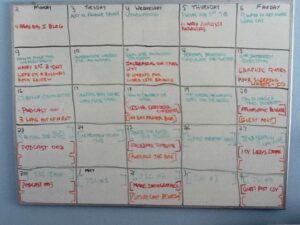

If you walk into your plant control room or scale house and look around, what do you see? Your plant operator or weighmaster watching the plant, loading a truck, answering phones… You see buttons, levers, and paperwork. You see EEO postings, lunch boxes, a calendar with a hot chick on a car, and most likely a whiteboard calendar of orders for the plant.

The Whiteboard to Excel/Outlook

Some operations have evolved from the whiteboard to shared excel calendars–that most likely get corrupted all the time. Maybe even an Outlook calendar that holds appointments containing information about asphalt orders for the coming days. Some have even tried to create their own solution, and spend a bunch of time and money. Most still have central dispatchers who control the schedule. Salespeople and Plant Operators field calls from customers, check with dispatch to ask what is scheduled, reply to the customer, and back and forth they go until a date presents itself. So, how can we cut down on the sheer number of calls, by having the information more available?

Some operations have evolved from the whiteboard to shared excel calendars–that most likely get corrupted all the time. Maybe even an Outlook calendar that holds appointments containing information about asphalt orders for the coming days. Some have even tried to create their own solution, and spend a bunch of time and money. Most still have central dispatchers who control the schedule. Salespeople and Plant Operators field calls from customers, check with dispatch to ask what is scheduled, reply to the customer, and back and forth they go until a date presents itself. So, how can we cut down on the sheer number of calls, by having the information more available?

CRM for the Every-Organization

Companies seek and struggle to find simple Customer Relationship Management (CRM) tools designed for asphalt plants, concrete plants, or quarries. With hundreds to choose from, and some that are decent, none are built for the construction materials industry. Expensive customization costs, or inventive work-arounds make the products viable, but not the right tool for the job. Applicable to both your construction materials team and the customers buying your products, Peter Thiel notes: “Customers won’t care about any particular technology unless it solves a particular problem in a superior way.” This is why many in our industry feel underwhelmed by the solutions currently available for scheduling plants, and communicating with our customers.

Now, imagine if a fresh, new iterative process was performed on the tools we use to schedule our plants.

PlantDemand came in to the industry with a clear, new directive: Use select plant people to imagine, inspire, and implement the best scheduling tool for plants. An expert team of visionary, user-interface gurus came together with a variety of construction materials people to conquer this quest. Hundreds of interviews, tests, and trials were conducted. The team wanted to get into the minds of their users, often opting to test newly developed features on either the largest critics, or people who would have a difficult time using the software. Critics give some of the best feedback on the little things that others might not notice. The next steps are where the fun starts…

- Take a person who just finished a double shift at a plant with little computer savvy,

- Show them the new features without any guidance.

- Ask them to complete a task.

- Take notes… and more notes

- Find any spots where these poor subjects struggled or got stuck

- Thank them, and let them sleep

- Code, hack, and develop until you think the next person will prevail

- Repeat

What results, when you mix up the recipe above, is the most efficient, easy, and effortless solution for creating a plant’s schedule. Orders could be created in under 11 seconds!

The Power of Visibility

If you were to take the section above, and make the product visible by everyone in the plants team, picture the result. Everyone would see what is coming up whenever they felt like looking. They could identify potential issues and conflicts that others might have missed far enough ahead of time to come up with a better solution. Salespeople could be out on the job with their customer, view the calendar, and schedule their materials immediately. And most of all… people were HAPPY. Finally something that they helped build, that is actually something they really like to use. The first plants used PlantDemand to schedule over 8 Million tons of material in the first year. Several HUGE conflicts were avoided, as well as hundreds of small ones. Plant Engineers, Superintendents, or Managers could create a production calendar, and view inventory forecasts based on production plans. Dispatch (or anyone) could share the daily dispatches for all of the plants in their operation in 5 clicks. Suppliers were given the material needs of the plants with 4 clicks. Management was given sales projections in 3. Plant Operators could tell what was on the schedule and what materials they needed in only 1! A tremendous success.

Partnering through the Customer Portal

The newest addition that keeps taking PlantDemand further, beyond other scheduling tools is the Customer Portal. By keeping the theme of “include everyone”, customers have a chance to see a version of your calendar too. It helps them know what days you are running which material, and create a quick request.

Work side by side PlantDemand

Right now, PlantDemand is cycling through their innovative loop and will be working with groups in the industry who fit well into their vision. The materials and construction companies that got into the first round of PlantDemand’s release have benefited tremendously, leaving other companies in the dust. And although the improvements will be released to all interested companies in the future, right now is a scarce moment in time. One, PlantDemand’s group is building their partner teams from the materials industry. They can help you problem solve and really pick the right software, or see how to help integrate your existing tools into theirs. Once they begin the new “Imaginate – Test – Iterate” cycle with the new select teams, that kind of valuable consulting will be hard to get. Two, industry change is happening so rapidly, that failing to choose a solution of any kind will be a business setback. Three, the number of plants using PlantDemand is growing rapidly, and they are very busy. Groups that get into PlantDemand early can get their plants set up with the help of the developers in only a day or two, so you can maximize your resources.

Like Ernest Ransome and his bridge–which still stood along with his other buildings and structures after the 1906 Earthquake–PlantDemand wants to work with people who share a similar vision and appreciation for making their operation better. If you feel like your company would be a good fit, and would like to be considered, fill out an Application HERE.

Or if you think someone you know might be a good fit, you can refer them, or email us with their contact information.

Attributes: