Introduction to asphalt planning

If you are planning to construct a new driveway, parking lot, or any other asphalt pavement, you should know that proper ground preparation is essential for the longevity and durability of your investment. Proper preparation of the ground, choosing the right type of asphalt, and laying it at the appropriate time are all crucial factors that determine the quality and longevity of your pavement.

In this article, we will guide you through everything you need to know about asphalt planning, including ground preparation, types of asphalt, and the best time to lay it.

Ground Preparation

Before laying asphalt, proper ground preparation is necessary to ensure a stable and durable base for your pavement. The first step is to remove any vegetation, debris, or existing pavement from the area. This step allows for a clean slate to begin building the base of the pavement.

The next step is to grade and level the soil to create a stable foundation. This process involves removing the topsoil and replacing it with gravel or crushed stone. The gravel or crushed stone should be compacted and leveled to create a solid base.

After the gravel or crushed stone is in place, the next step is to add a layer of binder. The binder is a mixture of asphalt, water, and an emulsifying agent that helps the asphalt adhere to the surface. The binder layer should be approximately two inches thick and evenly spread over the gravel or crushed stone.

Types of Asphalt

Asphalt is a mixture of aggregate, binder, and filler. The type of asphalt used for your pavement depends on the intended use, climate, and budget.

The two main types of asphalt are hot mix asphalt and cold mix asphalt. Hot mix asphalt is the most commonly used type of asphalt for pavements. It is made by heating asphalt binder to a high temperature and mixing it with aggregate. This mixture is then transported to the construction site and laid while still hot.

Cold mix asphalt, on the other hand, is made by mixing asphalt binder with aggregate at room temperature. This type of asphalt is less durable than hot mix asphalt but is suitable for small repairs or patching.

The Best Time to Lay Asphalt

The best time to lay asphalt depends on several factors, including the temperature and moisture content of the ground. Ideally, asphalt should be laid when the temperature is between 50 and 85 degrees Fahrenheit.

During hot weather, the asphalt can cool too quickly, which can cause cracking and other damages. During cold weather, the asphalt may not set properly, which can also lead to cracks and damages.

It is also important to lay asphalt when the ground is dry. Wet ground can cause the asphalt to slide and shift, leading to uneven surfaces and damages.

PlantDemand and Planning Asphalt Sales at an Asphalt Plant

PlantDemand is a revolutionary tool for asphalt producers that allows them to plan their production and sales with ease. With PlantDemand, asphalt producers can track their inventory, sales, and production schedules in real-time. The tool provides detailed reports and analytics, allowing producers to make informed decisions about their production and sales.

Using PlantDemand, asphalt producers can plan their production based on demand, ensuring that they have enough inventory to meet their customers’ needs. They can also schedule their production to avoid downtime and optimize their resources. PlantDemand helps producers to streamline their operations, reduce costs, and increase profitability.

Conclusion

Proper ground preparation, choosing the right type of asphalt, and laying it at the appropriate time are all crucial factors that determine the quality and longevity of your pavement. Taking the time to prepare the ground and choose the right type of asphalt can help ensure a stable and durable pavement that can withstand heavy use and weather conditions.

When planning your asphalt pavement, consult with a professional contractor to ensure that you are taking all the necessary steps to create a stable and durable surface. With proper planning and execution, your asphalt pavement can provide you with many years of use and enjoyment.

Sources:

- “Asphalt Pavement Alliance | Asphalt. America Rides On Us.” Asphalt Pavement Alliance, https://asphaltroads.org/.

- “Asphalt Paving Design Guide.” Asphalt Institute, https://asphaltinstitute.org/wp-content\

- “Asphalt Pavement Design Guide” by the National Asphalt Pavement Association provides an overview of the design process for asphalt pavements, including planning considerations. Link: https://www.asphaltpavement.org/wp-content/uploads/2020/03/Asphalt-Pavement-Design-Guide-2018.pdf

- “Asphalt Paving Design Guide” by the Asphalt Institute offers guidance on the design and construction of asphalt pavements, including planning and site preparation. Link: https://asphaltinstitute.org/wp-content/uploads/2019/05/MS-22-5th-Edition.pdf

- “Asphalt Mix Design and Construction: The Basics” by the Federal Highway Administration covers the basics of asphalt mix design and construction, including planning and materials considerations. Link: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/ltpp/16054/16054.pdf

- “Asphalt Construction and Maintenance” by the Minnesota Department of Transportation provides guidance on the planning, design, and maintenance of asphalt pavements. Link: https://www.dot.state.mn.us/materials/pavement/pdf/asphalt-construction-maintenance.pdf

- “Asphalt Roadway Rehabilitation Guide for Local Governments” by the Wisconsin Department of Transportation offers advice on planning and implementing asphalt roadway rehabilitation projects. Link: https://wisconsindot.gov/Documents/safety/education/ltap/asphalt-roadway-rehabilitation.pdf

Other posts

-

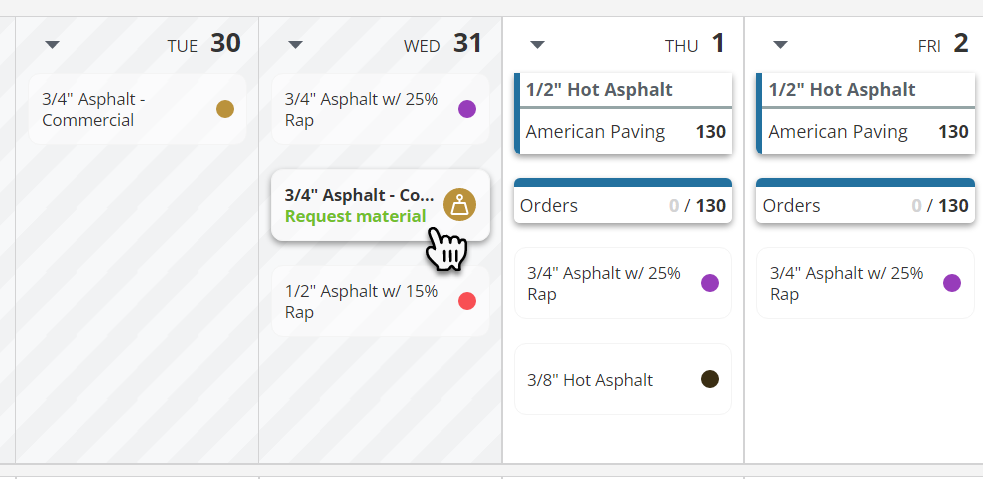

Requesting Asphalt and Aggregate From Your Plant – A Customer Portal Update

Customers can request asphalt and aggregates from your plant The Customer Portal was initially released in PlantDemand to allow customers to submit requests for mix to your plant. They could see the status of their request, and then see it on the calendar once a plant person approved it. While […]

-

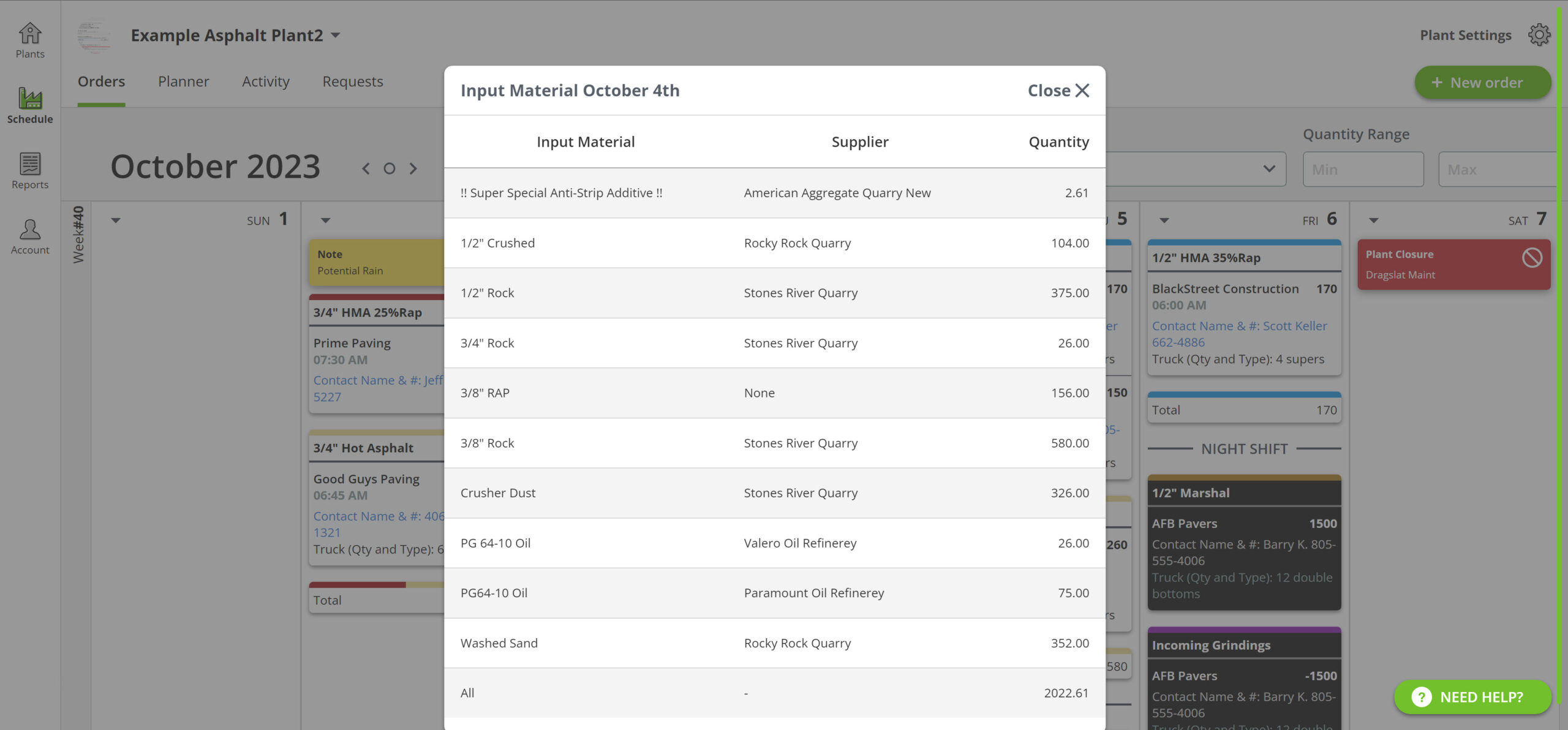

Creating Mix Designs and Materials in PlantDemand

Create Mix Designs and Materials To create materials in PlantDemand, follow the steps below. Edit your mix designs periodically. Make output materials obsolete if your mix design has expired. This will make it so that it can no longer be scheduled, and will put an “Obsolete” tag to the front […]

-

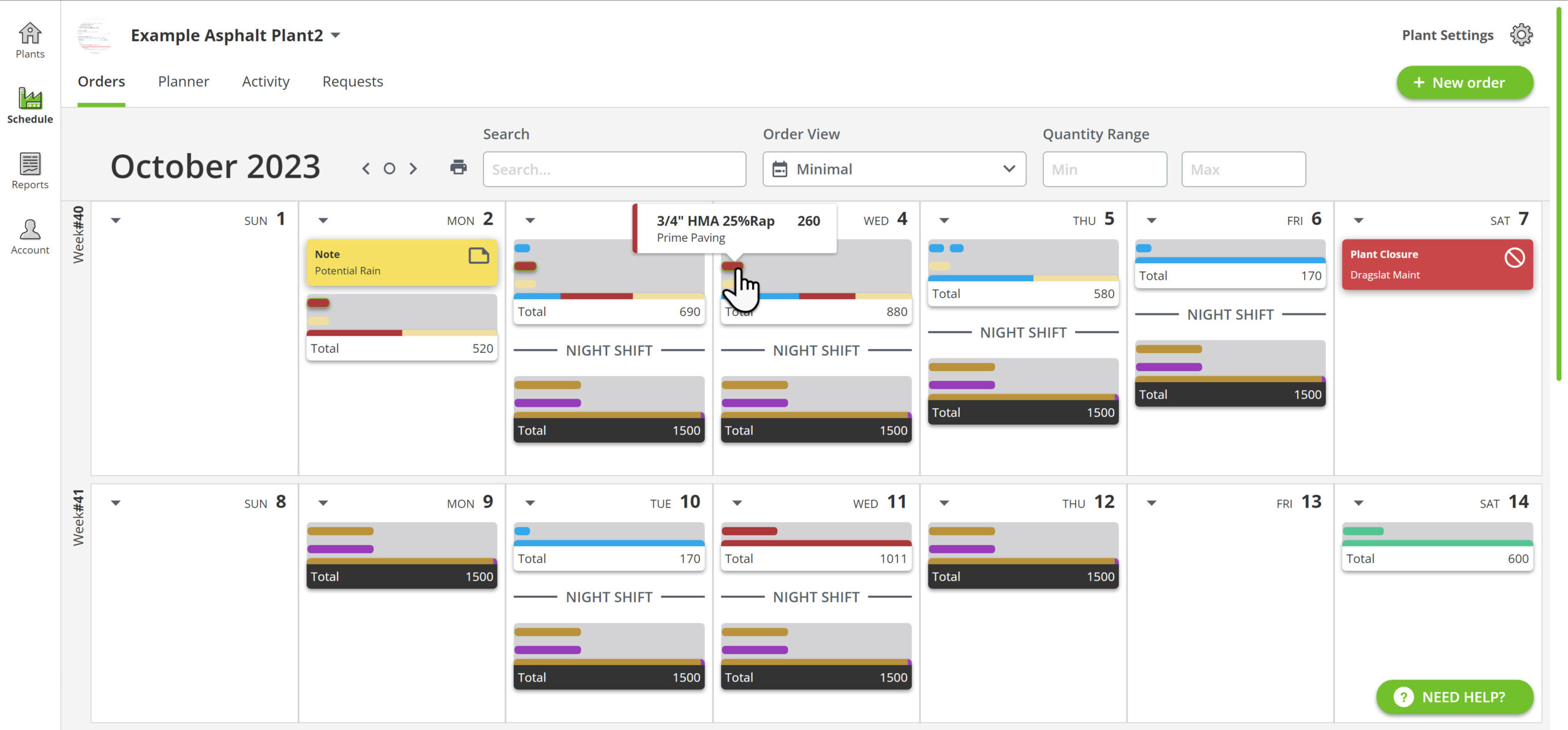

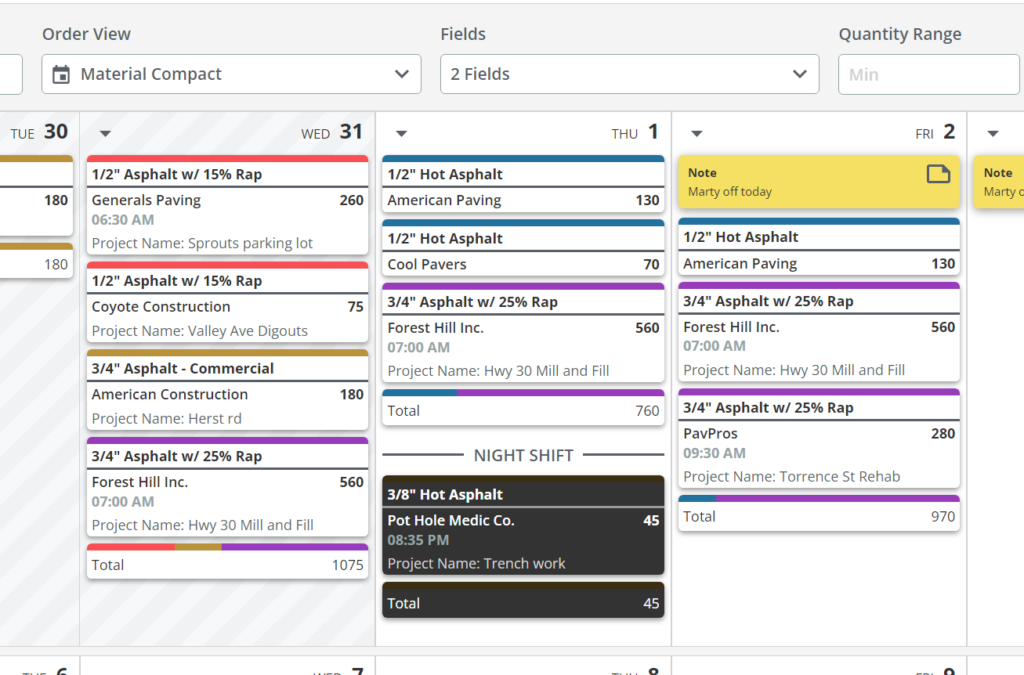

8 Common Mistakes in Asphalt Software and Scheduling

Key Takeaways Aspect Description Calendar Views While the Material View is the default when getting started, many users don’t explore PlantDemand’s other calendar views Important Custom Order Fields Your order form can have fields that are important to your plant and business. Select important fields to show on your calendar […]