Introduction

- Explanation of Warm Mix Asphalt (WMA)

- Advantages of WMA over traditional Hot Mix Asphalt (HMA)

How it is Made

- Explanation of the different production methods of WMA

- How WMA is produced at lower temperatures compared to HMA

Benefits of Using Foamed Warm Mix

- Environmental benefits of using WMA

- Cost-saving benefits of using WMA

Performance of Warm Mix

- Durability of WMA compared to HMA

- Evaluation of the skid resistance and texture of WMA

Implementation of Warm Mix Black Top

- Case studies of WMA application in different countries

- Use of WMA in different types of road construction

Potential Challenges and Solutions for Warm Mix Asphalt

- Common challenges faced when using WMA

- Techniques to overcome challenges when using WMA

Future of Warm Mix Asphalt

- Ongoing research and development of WMA

- Potential for WMA to become the preferred method for road paving

Conclusion

- Recap of the advantages of WMA over HMA

- Encouragement for the increased use of WMA in road construction

Warm Mix Asphalt: A Revolutionary Way to Pave Roads

Asphalt is the backbone of modern road construction and has been used to pave roads for more than a century. Traditionally, Hot Mix Asphalt (HMA) has been the standard method used to pave roads. However, with the advancement of asphalt technology, a new and improved method of paving roads has emerged – Warm Mix Asphalt (WMA). In this article, we will explore the benefits and advantages of using WMA, as well as the production, performance, and implementation of this revolutionary paving method.

Introduction

WMA is a type of asphalt that is produced and laid at lower temperatures compared to HMA. The production of WMA involves the use of additives that allow asphalt to be produced and compacted at temperatures that are up to 50 degrees Celsius lower than those used in HMA production. WMA has several advantages over traditional HMA, including improved workability, energy savings, and reduced carbon emissions.

How Warm Mix is Made

WMA can be produced using various methods, including foaming, water injection, and chemical additives. Foaming is the most common method used in WMA production, which involves introducing a small amount of water into hot asphalt binder to produce foam. The foam allows the asphalt to be easily mixed and compacted at lower temperatures.

Benefits of Using WMA

WMA has many benefits compared to HMA, including environmental and cost-saving benefits. The production and laying of WMA require less energy, reducing fuel consumption and resulting in lower carbon emissions. WMA also has lower production costs, as it requires less energy and lower operating temperatures compared to HMA.

Performance of Warm Mix

Studies have shown that WMA has a similar or better performance than HMA. WMA has been found to have better resistance to moisture damage, resulting in better durability compared to HMA. The texture of WMA is also superior to HMA, providing better skid resistance and safety on roads.

Implementation of Warm Mix Systems and Pavements

WMA has been implemented in various road construction projects worldwide, including in Europe, Asia, and the United States. WMA has been used in various road types, including high-traffic highways and low-traffic roads. The use of WMA has also been encouraged by governments worldwide, including the United States Environmental Protection Agency, which has recommended the use of WMA in federal road construction projects.

Potential Challenges and Solutions for Warm Mix Pavement

Common challenges faced when using WMA include shorter working times and reduced compaction time compared to HMA. However, techniques such as the use of warm mix asphalt additives and advanced equipment can help to overcome these challenges. Proper training of workers and implementing best practices can also help to ensure the successful implementation of WMA.

Future of Warm Mixes

The use of WMA is gaining popularity worldwide, and ongoing research and development are focused on further improving this technology. The development of new additives and production methods is underway, which could lead to even more significant environmental and economic benefits. With the growing concerns over climate change and sustainability, the future of WMA looks bright, and it has the potential to become the preferred method for road paving.

Conclusion

In conclusion, Warm Mix is a revolutionary way of paving roads that offers several advantages over traditional Hot Mix Asphalt. WMA is environmentally friendly, cost-effective, and has superior performance compared to HMA. With proper implementation and ongoing research and development, the use of WMA will continue to grow, contributing to the sustainability and safety of road infrastructure worldwide.

FAQs

- Is Warm Mix AC more expensive than traditional Hot Mix Asphalt?

No, WMA is less expensive to produce than HMA as it requires less energy and lower operating temperatures.

- Is WMA durable compared to HMA?

Yes, studies have shown that WMA is more durable and has better resistance to moisture damage compared to HMA.

- Is Warm Mix Asphalt safe for high-traffic highways?

Yes, WMA has been used in various road types, including high-traffic highways, and has been found to provide better skid resistance and safety on roads.

- What are the potential challenges of using Warm Mix Asphalt?

Challenges of using WMA include shorter working times and reduced compaction time compared to HMA. However, techniques and best practices can help to overcome these challenges.

- What is the future of Warm Mix Asphalt?

The use of WMA is gaining popularity worldwide, and ongoing research and development is focused on further improving this technology, making it more environmentally friendly and economically viable.

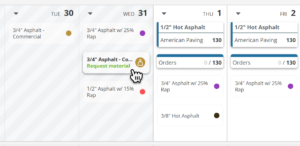

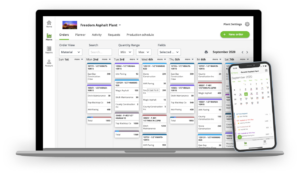

- Requesting Asphalt and Aggregate From Your Plant – A Customer Portal UpdateCustomers can request asphalt and aggregates from your plant The Customer Portal was initially released in PlantDemand to allow customers to submit requests for mix to your plant. They could see the status of their request, and then see it on the calendar once a plant person approved it. While […]

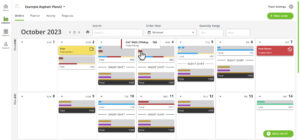

- Creating Mix Designs and Materials in PlantDemandCreate Mix Designs and Materials To create materials in PlantDemand, follow the steps below. Edit your mix designs periodically. Make output materials obsolete if your mix design has expired. This will make it so that it can no longer be scheduled, and will put an “Obsolete” tag to the front […]

- 8 Common Mistakes in Asphalt Software and SchedulingKey Takeaways Aspect Description Calendar Views While the Material View is the default when getting started, many users don’t explore PlantDemand’s other calendar views Important Custom Order Fields Your order form can have fields that are important to your plant and business. Select important fields to show on your calendar […]

- PlantDemand Upgrades Customer Portal for Streamlined Requests and SchedulingNews Distribution: PlantDemand Upgrades Customer Portal for Streamlined Requests and Scheduling PlantDemand, the leading online asphalt plant scheduling software, announces the release of an updated version of its Customer Portal. The new and improved portal provides customers with an even more seamless and efficient way to request plant services and […]

- Ahorra tiempo, mejora la gestión de materiales y la programación de pedidos con PlantDemandLa nueva tecnología ayuda a simplificar las operaciones de las plantas de asfalto El software de asfalto PlantDemand mejora significativamente la gestión de materiales y la programación de pedidos, ahorrando tiempo y dinero Por JESSICA LOMBARDO 24 DE ENERO DE 2022 Los empleados de las plantas de asfalto saben que […]

Sources

- “Warm Mix Asphalt – Benefits and Challenges.” National Asphalt Pavement Association. https://www.asphaltpavement.org/docs/default-source/research-and-tech/ncat-report-18-04-wma-benefits-and-challenges.pdf

- “Warm Mix Asphalt: An Overview.” Federal Highway Administration. https://www.fhwa.dot.gov/pavement/asphalt/wma.cfm

- “Warm Mix Asphalt: A Technique That’s Friendlier to the Environment.” Engineering News-Record. https://www.enr.com/articles/38723-warm-mix-asphalt-a-technique-thats-friendlier-to-the-environment

- “Scheduling Warm Mix Asphalt” PlantDemand. https://plantdemand.com/