Aggregate and Quarry Production and Inventory Planning / Forecasting

Schedule Production and Modify Modes for Aggregate Plants and Quarries in PlantDemand to forecast inventory and maximize cashflow.

Having a live sales calendar paired with you production plan will allow you to make adjustments to you plant, hours, modes and sales so that you can solve inventory issues far in advance. Seeing potential run-outs or excessive inventory ahead of time will allow you to plan your operations with you team. Your plant foreman, superintendent, engineer, and sales people can use PlantDemand to see where they might have issues, so they can work together to plan a solution before it’s too late.

This video will quickly walk you through PlantDemands simple production schedule, production report, and inventory forecast.

How it works

Make sure your plant type is set to “aggregate plant” when you create it (Settings -gear- Tab > General). And next, create some Output Materials (Settings tab > Mix Designs > click “+” to the right of “Output Materials” dropdown .

Be sure to spend some time discussing and deciding appropriate Minimum Required, and Maximum Desired inventories for each product. Take into account your site, historic and upcoming sales volumes, demand, etc. This is a great practice to help maintain good cash flow, but still keep the necessary amount of material in inventory without the risk of a Run-Out.

Now setup some production modes. You can create production modes by going to the settings tab, and then to “Production Mode”. Here, you can add a new mode, review current ones or make adjustments. The default tons per hour will be stored so that when you create a production plan for that mode, it will automatically pull in the rate you’ve entered here. Next, enter your Output Materials in their respective percentages. You can even add Waste as a product in you mode, so you can account for it.

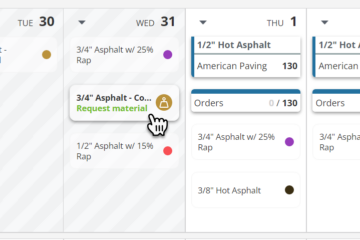

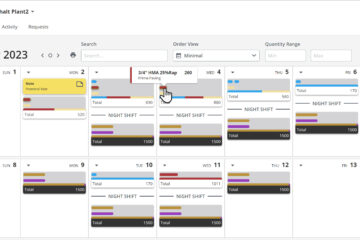

Go to the “Production Schedule tab above the calendar. Click on a date to create a production plan. Increasing or decreasing the production rate or hours per day will change the height of the mode bars in your production schedule.

Reporting

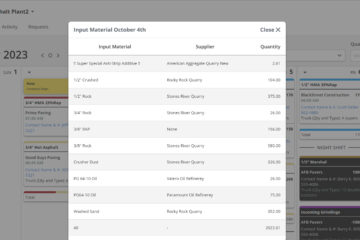

The production rate, hours per day, and that mode’s output percentages will be used to report the total quantity produced by product. These quantities can be viewed in the Production Report.

So, how will the production plan we have created affect our Inventory Forecast? The orders on the live PlantDemand sales calendar will be paired with the production calendar, giving you the resulting changes to inventory. View the Inventory Forecast in the Reports Tab, and click the drop down to select the Inventory Forecast report.

Enter your current Inventory for each product, and quickly see where you will have issues. Quantities highlighted in blue represent an overabundance of inventory, where red represents the risk of a run-out. Adjusting your production modes, your hours, or making changes to the plant are some of the ways to resolve these issues. Conversations with your sales team and customers about these complications are another great way to fix them.

Getting your plant, production, sales and inventories into balance is the key to maximizing profits, cashflow, and flexibility.

Learn More

Check out our other videos in the Academy to learn more.

Get your Asphalt, Ready-Mix, or Aggregate Plants up and running on PlantDemand in less than a day.

Keywords: Asphalt Plant, Asphalt Production, Asphalt Scheduling. Concrete Plant, Concrete Production, Concrete Scheduling. Aggregate Plant, Aggregate Plant Scheduling. Aggregate Plant Production Planning. Aggregate Plant Inventory Forecasting