Cash Flow In Aggregate Plants

{5 minute read}

Would you ever go to the store and buy $2,000 worth of toilet paper? Throughout your lifetime you are probably going to use it. But, unless you just ate some really bad Indian food, or are stocking up for the global apocalypse–it doesn’t make any damn sense. There is something better you could be doing with that money.

The words ‘Negative Cash Flow’ are some of the most terrifying words for plant managers or materials businesses. A major focus on cash flow management for aggregate plants and quarries has come center stage over the past several years during the economic downturn of the 2008 recession. Plants used to have the luxury of building vast amounts of inventory to get through breakdowns, or for the unexpected large material sale. And with balance sheet accounting, those large inventories would create profit. But, after all, these companies couldn’t pay the bill for their loader fuel with profits. They pay them with cash. They couldn’t pay their employees with the inventories (profits) they created. They had to pay with cash. But before we go down the accountant’s rabbit hole and discuss advanced account models, EBITDA, or other principals, I will keep it simple and assume that you have found this article because you already know something about cash flow. I will also presume that you are here because you are searching for a tool that will help you EXECUTE better cash flow, specifically in the area of production, sales, and inventory management in your aggregate plant. And, lastly, I will presume you are looking for a great way to do it.

Managing Inventory in Aggregate Plants

‘Inventory management’ is the component of a materials operations plant managers and engineers have enormous impact on due to their decisions. Oftentimes they are in full control. So what is a good target to understand how well you are managing your inventory? After all, inventory is a massive liability in terms of cash flow. One measurement is done by looking at expected sales, and trying to maximize the number of inventory turns at your plant. This means the number of times a pile of a certain rock could be sold in a single year, based on the current inventory. For example: Your base rock pile is 20,000 tons, and you sell 100,000 tons per year. You would have 5 inventory turns per year. This would be a great target for every product you carry. The higher the number of turns, the better the cash flow for your business.

The three things that we need to know and effect to improve cash flow are Sales, Current Inventory, and Production. And as dynamic as these three items are, we must be just as dynamic–and strategic–in how we manage them. Things change fast in this business, and making adjustments quickly to positively affect the outcomes is what makes a plant business great.

Sales Calendar for Aggregate Plants and Quarries

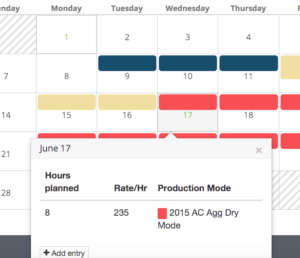

Sales drives everything. Eliyahu Goldratt said in The Goal, “Throughput is the rate at which the system generates money through sales”. Meaning no matter how fast you make different products, it is useless unless you have sales of each product matching the rates they are being produced. Having good sales forecasts is the key component to beginning to increase your cash flow and manage inventory. Many of us use historical data to find trends in material sales. Also, many of us have a good feel for what products sell better than others. Effectively using past information and combining it with future backlog is crucial in the quest to becoming a first class materials operations. There are many ERP systems and sales tracking systems on the market. Every company has something in place to track actual sales. But what about scheduling and planning for upcoming sales. Online aggregate plant sales calendars can help with this. There are even great tools for customers to view your plant schedule, and create order requests–helping you get a more accurate understanding of your customers needs. The more information you have about upcoming sales, the more of an advantage you will have in maximizing cash flow.

Inventory Measurements for Quarries and Agg Plants

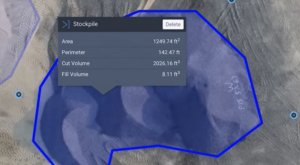

Beginning your inventory planning starts with having good information of your current inventory. This used to take days or weeks to get measurements of each pile, but with cool new tools like the Kespry Drone it makes the task faster and easier. What a fun way to go measure your piles, compared to the tiring methods of the past.

Beginning your inventory planning starts with having good information of your current inventory. This used to take days or weeks to get measurements of each pile, but with cool new tools like the Kespry Drone it makes the task faster and easier. What a fun way to go measure your piles, compared to the tiring methods of the past.

While tools like the Kespry can get pretty exact, sometimes just having a good idea of the inventory to the nearest few hundred, and sometimes thousand tons is a good starting point in creating inventory projections. After all, can you actually replicate the unit weight of a 40,000 ton pile by running the test on such a tiny sample?

Production Planning and Scheduling in Quarries and Aggregate Plants

We are all probably pressured to be more productive, get more tonnage through the plant, get more product on the ground, increase tons per man hour, and on and on. But what if what you are producing is actually hurting you? Peter Drucker said, “Nothing is less productive than to make more efficient what should not be done at all”. Running faster, and getting more of the wrong products out of the plant is doing nothing but burning your cash. Sometimes, it is actually better to slow down, and make more of what you NEED.

Most of your plants have a few main modes, with tons of variations. Once you have an idea of what your sales goals or schedule is, and have put together a good estimate of your current inventories you can begin your production plans. But ONLY begin…

Now, Here is Where the Fun Starts…

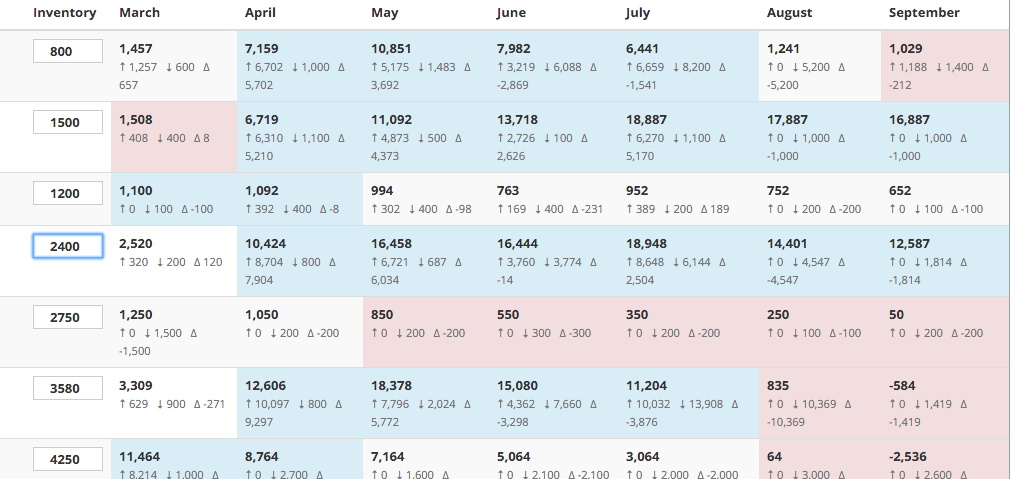

Setting target inventory ranges for each individual product is where you can actually start to affect cash flow. Sitting down with your sales team, plant foreman or superintendent, and even some customers to discuss upcoming needs and the capabilities of your plant will narrow down your prefered ranges. Setting a maximum desired inventory will create the upper limit of material you can have on the ground. Discussing the lower limit will define what the least amount of each product you want to have, without putting yourself in a position of a runout.

The Inventory Forecast on the above shows materials in blue that will have too high of inventory (hurting your cash flow), while products in red are at risk of a run-out. So what do you do?

Sales, Inventory and Production… that’s what you CAN control. It’s time to pull in your people and come up with a plan. First, adjusting production modes and number of days in each mode can help you get where you need to be. If that does not get you there, you might look at the plant and change some things to increase or decrease out-of-balance products. If you have done all you can, it’s time to look at what can be done on the sales front. Iterate through the process until you have an inventory forecast that keeps you where you want to be.

As you and your team go through this process a few times, you will start to shrink your range of desired inventory quantity, your team will have a better understanding of the plant capabilities, and you will have a better handle on your cash.

Get started now by clicking here